|

The AC890PX Modular Chassis variable speed AC drives are supplied in kit form saving space, time and components. The AC890PX-M Provides systems integrators and panel builders with the flexibility to assemble the drive into the same suite of electrical enclosures as the additional ancillary control components required to tailor the product to meet the needs of their customer‘s applications. Available in a wide range of power ratings for both constant and variable torque applications, the dual-mode AC890PX Modular Chassis Drive provides a cost effective solution for industrial process applications, as well as energy-saving control of larger power pumps and fans.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads  Request additional information and get a price quote Request additional information and get a price quote |

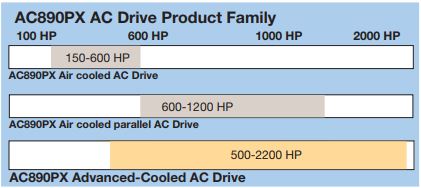

Model range

AC890PX system building series (3 phase 380-480 V) / HD

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Price | |

|---|---|---|---|---|---|

| 890PX/4/0215 | 110 | 215 | 0-3000 | reduced! | |

| 890PX/4/0260 | 132 | 260 | 0-3000 | reduced! | |

| 890PX/4/0300 | 160 | 300 | 0-3000 | reduced! | |

| 890PX/4/0420 | 200 | 420 | 0-3000 | reduced! | |

| 890PX/4/0480 | 250 | 480 | 0-3000 | reduced! | |

| 890PX/4/0520 | 280 | 520 | 0-3000 | reduced! | |

| 890PX/4/0580 | 315 | 580 | 0-3000 | reduced! | |

AC890PX system building series (3 phase 380-480 V) / ND

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Price | |

|---|---|---|---|---|---|

| 890PX/4/0215 | 132 | 260 | 0-3000 | reduced! | |

| 890PX/4/0260 | 160 | 340 | 0-3000 | reduced! | |

Parker AC890PX series high power modular AC drive with advanced cooling technology.

The AC890PX is an innovative, modular, high power AC drive system, that has been developed to minimize drive footprint and reduce installation time and costs, for a range of motor control applications. The AC890PX is delivered as a complete package, ready for connection to the power supply and motor.

Increased Power Density with Advanced Cooling System.

With the introduction of an innovative Parkerengineered cooling system, the AC890PX series offers increased power output in a compact drive footprint. The Advanced Cooling design uses a high efficiency hermetically sealed and maintenance-free system.

Multiple Configurations.

While this catalog focuses on the standalone drive version, the AC890PX is also available as a DC input inverter and a complete regenerative drive with active front end.

Applications.

The AC890PX is suited to many different motor control applications, where power density and compactness are key design considerations.

- Pumps

- Automotive Test Stands

- Extruders

- Decanter and batch centrifuges

- Hoists and cranes

- Winder/unwind stands

- Ski lifts and cable cars

- Offshore and marine

Advanced Cooling System.

Advanced Cooling Process.

The AC890PX Series Advanced Cooling design draws from years of Parker experience in refrigeration technology combined with state of the art drive design to produce a truly high-performance, yet compact AC drive range. The unique two-phase coolant system rapidly absorbs heat from drive IGBTs in the coolant’s change of phase from liquid to vapor. The coolant is safe, non-conductive, and non-corrosive. The system itself is hermetically sealed, requiring no routine maintenance. Compared to water cooling systems, this requires much less liquid to be pumped and reduces the thermal cycling of the drive electronics while maintaining performance. A condenser unit, mounted above the drive, is available in either coolant to air or coolant to liquid varieties.

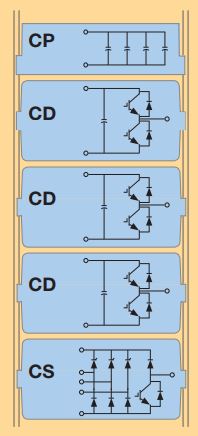

Compact Modular Design.

The plug-in modular nature of the AC890PX makes it easy to configure the drive to suit a number of alternative input power configurations including 12 or 18 pulse and Active Front End (AFE). The 'PowerPak' phase modules, common supply modules, capacitor and control module can be arranged to suit the particular requirements of the application.

Low-maintenance ensures maximum machine up-time and productivity.

By virtue of a unique plug-in design, the rack mount power modules of the AC890PX drive are replaceable in minutes by any technician, even a non-specialist. These lightweight, ship anywhere modules help to reduce machine or process downtime and lost productivity in the event of a fault occurring. AC890PX drives can be configured with different module combinations dependant upon the application.

CP Module:

- The capacitor module, where included, provides extra capacitance for the DC bus.

CD Module:

- These output phase modules each provide a single phase of the complete drive and can be interchanged with each other.

CS Module:

- A 3-phase input rectifier containing a half-controlled diode/thyristor bridge. This module supplies DC to the three CD modules and can include an integral dynamic brake switch. (Used in AC fed units only)

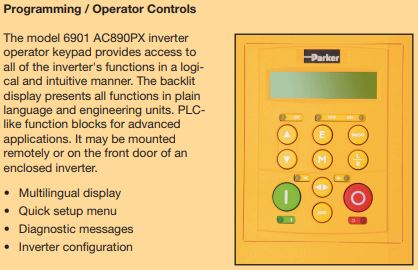

Parker drive AC890PX Series tools.

Inverter and Vector Duty Induction Motors 1 - 500 HP.

Parker SSD can provide Inverter Duty and Vector Duty motors that let you get the most out of your drive. With your choice of a wide variety of frame styles, every rating includes specific features demanded by high performance drive applications. Cast iron frames with totally enclosed non-ventilated construction are available for harsh environments, while compact laminated frame designs with forced ventilation can fit into the tightest spaces while providing 1000:1 constant torque speed range and excellent dynamic performance. Not all motors are created equal. Don’t settle for a re-rated constant speed motor for variable speed applications. All Parker SSD Inverter and Vector Duty motors are provided with insulation that is suitable for use with IGBT based PWM drives, and with 200% torque overload capability. Ask for a performance matched package every time.