|

The Altivar Machine ATV320 drive is a variable speed drive for three-phase asynchronous and synchronous motors from 0.18 to 15 kW. The Altivar Machine ATV320 drive is robust, simple to commission, and easy to integrate into different machine layouts and cabinets. It can also be integrated into commonly used automation architectures. Altivar Machine ATV320 variable speed drives are particularly suitable for applications involving simple industrial machines. Furthermore, Altivar Machine ATV320 embeds many practical functions so that advanced application requirements can be covered. Altivar Machine ATV320 is designed to improve machine performance and increase machine availability while reducing the total machine cost.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads  Request additional information and get a price quote Request additional information and get a price quote |

Model range

Altivar Machine ATV320 (1 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| ATV320U02M2C | 0.18 | 1.5 | 72x188x109 | 168,00 € | |

| ATV320U04M2C | 0.37 | 3.3 | 72x188x138 | 174,00 € | |

| ATV320U06M2C | 0.55 | 3.7 | 72x188x138 | 194,00 € | |

| ATV320U07M2C | 0.75 | 4.8 | 72x188x138 | 207,00 € | |

| ATV320U11M2C | 1.1 | 6.9 | 105x188x158 | 239,00 € | |

| ATV320U15M2C | 1.5 | 8 | 105x188x158 | 278,00 € | |

| ATV320U22M2C | 2.2 | 11 | 105x188x158 | 329,00 € | |

Altivar Machine ATV320 (3 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| ATV320U02M3C | 0,18 | 1.5 | 72x143x109 | reduced! | |

| ATV320U04M3C | 0,37 | 3.3 | 72x143x128 | reduced! | |

| ATV320U06M3C | 0,55 | 3.7 | 72x143x138 | reduced! | |

| ATV320U07M3C | 0.75 | 4.8 | 72x143x138 | 188,00 € | |

| ATV320U11M3C | 1.1 | 6.9 | 105x143x138 | 221,00 € | |

| ATV320U15M3C | 1,5 | 8 | 105x143x138 | reduced! | |

| ATV320U22M3C | 2.2 | 11 | 105x143x138 | 324,00 € | |

| ATV320U30M3C | 3 | 13.7 | 140x184x158 | 421,00 € | |

| ATV320U40M3C | 4 | 17.5 | 140x184x158 | reduced! | |

| ATV320U55M3C | 5,5 | 27.5 | 150x232x178 | reduced! | |

| ATV320U75M3C | 7,5 | 33 | 150x232x178 | reduced! | |

| ATV320D11M3C | 11 | 54 | 180x330x198 | 809,00 € | |

| ATV320D15M3C | 15 | 66 | 180x330x198 | reduced! | |

Altivar Machine ATV320 (3 phase 380-500 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| ATV320U04N4B | 0.37 | 1.5 | 45x325x245 | 196,00 € | |

| ATV320U06N4B | 0.55 | 1.9 | 45x325x245 | 228,00 € | |

| ATV320U07N4B | 0.75 | 2.3 | 45x325x245 | 242,00 € | |

| ATV320U11N4B | 1.1 | 3 | 45x325x245 | 276,00 € | |

| ATV320U15N4B | 1.5 | 4.1 | 45x325x245 | 294,00 € | |

| ATV320U22N4B | 2.2 | 5.5 | 60x325x245 | 347,00 € | |

| ATV320U30N4B | 3 | 7.1 | 60x325x245 | 392,00 € | |

| ATV320U40N4B | 4 | 9.5 | 60x325x245 | 447,00 € | |

| ATV320U55N4B | 5.5 | 14.3 | 150x308x232 | 472,00 € | |

| ATV320U75N4B | 7.5 | 17 | 150x308x232 | 569,00 € | |

| ATV320D11N4B | 11 | 27.7 | 180x404x232 | 671,00 € | |

| ATV320D15N4B | 15 | 33 | 180x404x232 | 773,00 € | |

Schneider Electric frequency inverter Altivar Machine ATV320 series machine solutions

The Altivar Machine ATV320 provides IP20 and IP6x variable speed drive for three-phase synchronous and asynchronous motors in open loop control, and incorporates functions suitable for the most common applications, including:

- Torque and speed accuracy at very low speed, high dynamic performance with flux vector control without sensor.

- Extended frequency range for high-speed motors.

- Parallel connection of motors and special drives using the voltage/frequency ratio.

- Static speed accuracy and energy saving for open-loop synchronous motors.

The Altivar Machine ATV320 series is focused on easy integration for simple and advanced machine requirements with proven motor control and connectivity. It offers enhanced automation capabilities and performance for industrial machine applications:

- Effective control of asynchronous and permanent magnet motors

- Complete integration into any system architecture (Ethernet, CANopen, Profibus, etc.)

- Compact and book format for integration in a variety of different cabinet types

- Integrated safety function for compliance with functional safety standards

- Enhanced resistance to polluted atmospheres

By taking account of constraints on product setup and use right from the design stage, Schneider Electric simplifies the integration of the Altivar Machine ATV320 drive into industrial machines. It features more than 150 functions. It is robust, easy to install, and compliant with the Machinery Directive 2006/42/EC. ATV320 is fully integrated inside Schneider Electric’s EcoStruxure Machine through DTM. PLCopen-compliant libraries. SoMachine can be used to develop, configure, and set up an entire machine in a single software environment. Using FDT/DTM technology, it is possible to configure, control, and diagnose Altivar Machine ATV320 drives directly in SoMachine and SoMove software by means of the same software brick (DTM). With seamless integration under this platform, Altivar Machine ATV320 benefits from the advantage of shorter engineering and design times. Optional Ethernetbased communication capability makes it accessible to production data at any level of automation system.

Schneider Electric drive Altivar Machine ATV320 series applications

Altivar Machine ATV320 drives incorporate functions suitable for the most common applications, including:

Material handling

- Very quick response times on transmission of a command: 2 ms (± 0.5 ms)

- Reference via pulse input as analog input

- Control via built-in CANopen network or optional communication networks

- Position control via limit switches with time optimization at low speed

- Multiple parameter settings via parameter set switching

- Provide high protection version IP65/66 product, with/without vario swtich

Hoisting

- Brake control adapted for horizontal and vertical movement

- Brake feedback management

- Load measurement using weight sensor

- High-speed hoisting with rope slack

- Limit switch management

- Dedicated speed monitoring function with optional card

- Multiple motors/configurations

- High speed switching function

- DC sharing and optional compact design regenerative braking unit

Packaging machines

- Up to 50 Hz of the bandwidth

- Control via built-in CANopen network or optional communication networks

- Book format enables to save space inside enclosure

- Advanced synchronous open loop control achieve energy saving performance

- Direct mounting of short circuit breaker on drive without wiring

Material working

- 5 integrated safety functions secure operation

- Control via built-in CANopen network or optional communication networks

- Fastest possible controlled stop on loss of line supply,

- Motor thermal monitoring and protection function

- Torque limitation

- DC sharing and optional compact design regenerative braking unit(ATV regene)

- Very quick response times on transmission of a command: 2 ms (± 0.5 ms) b 200% over torque ability,allow more dynamic response

Textile

- High protection degree version: IP65/IP66

- High resolution of the digital speed reference

- Use of synchronous motor, irrespective of load, helps to assure speed accuracy and energy saving

- High bandwidth with high-performance speed loop

- Spooling function/ Traverse control

- DC sharing and optional compact design regenerative braking unit

- Fastest possible controlled stop on loss of line supply secure continuous working machine

- Control via built-in CANopen network or optional communication networks

- Book format enables to save space inside enclosure

Pumping

- Dedicated motor control law for pumping and fan with optimized energy saving

- PID regulator with preset reference

- Multi motor parameter set

- ATV logic, programming function integrated in drive

- High protection degree enclosure

- Alarm management function

- Process load monitoring function

- Fault inhibition function,used in emergency situation such as smoke extraction.

General machine control

- ATV logic, programming function integrated in drive

- PID regulator

- 16 preset speed functions.

- Reference operation

- Line contactor and output contactor command

- Speed or torque control with current limitation

- Control via built-in CANopen network or optional communication networks

- DC bus management

- 6 motor control laws: Standard V/F,V/F 5 points, Sensorless vector control, Synchronous permanent magnet motors control, Variable torque, and Energy saving, allow user to adapt different machine behavior.

Integrated safety functions of Schneider Electric vfd Altivar Machine ATV320 series

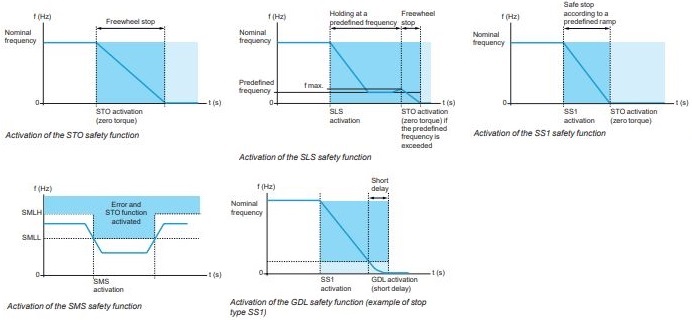

Safe Torque Off (STO) safety function

This function brings the machine safely into a no-torque state and/or prevents it from starting accidentally.

Safely Limited Speed (SLS) safety function

The SLS integrated safety function can be initiated by activation of safety function inputs. This function prevents the motor from exceeding the specified speed limit. If the motor speed exceeds the specified speed limit value, safety function STO is triggered.

Safe Stop 1 (SS1) safety function

The SS1 integrated safety function causes a category 1 safe stop. This function monitors the deceleration according to a dedicated deceleration ramp and safely shuts off the torque once standstill has been achieved.

Safe Maximum Speed (SMS) safety function

This function prevents the speed of the motor from exceeding the predefined speed limit.

- 2 different speed limits can be defined and can be selected by logic inputs.

- If the motor speed exceeds the predefined speed limit value, safety function STO is triggered.

Once the SMS function is configured, it is continuously active.

Guard Door Locking (GDL) safety function

This function allows you to release the guard door lock after specified delay when the motor power is turned off. The specified delay is chosen according to the type of stop. The front door of the machine can be opened only after the motor is stopped; this function helps to ensure the safety of the machine operator.