|

The P1000 drive provides simple, reliable, cost-effective control for variable-torque loads through 1000 HP. Specific application features, energy savings, and network connectivity make the P1000 a great choice for industrial fans and pumps.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

P1000 series for pump application (3 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Price | |

|---|---|---|---|---|---|

| CIMR-PU2A0004 | 0,75 | 3.5 | 0-6000 | reduced! | |

| CIMR-PU2A0006 | 1,1 | 6 | 0-6000 | reduced! | |

| CIMR-PU2A0008 | 1,5 | 8 | 0-6000 | reduced! | |

| CIMR-PU2A0010 | 2,2 | 9.6 | 0-6000 | reduced! | |

| CIMR-PU2A0012 | 3 | 12 | 0-6000 | reduced! | |

| CIMR-PU2A0018 | 3,7 | 17.5 | 0-6000 | reduced! | |

| CIMR-PU2A0021 | 5,5 | 21 | 0-6000 | reduced! | |

| CIMR-PU2A0030 | 7,5 | 30 | 0-6000 | reduced! | |

| CIMR-PU2A0040 | 11 | 40 | 0-6000 | reduced! | |

| CIMR-PU2A0056 | 15 | 56 | 0-6000 | reduced! | |

| CIMR-PU2A0069 | 18,5 | 69 | 0-6000 | reduced! | |

| CIMR-PU2A0081 | 22 | 81 | 0-6000 | reduced! | |

| CIMR-PU2A0110 | 30 | 110 | 0-6000 | reduced! | |

| CIMR-PU2A0138 | 37 | 138 | 0-6000 | reduced! | |

| CIMR-PU2A0169 | 45 | 169 | 0-6000 | reduced! | |

| CIMR-PU2A0211 | 55 | 211 | 0-6000 | reduced! | |

| CIMR-PU2A0250 | 75 | 250 | 0-6000 | reduced! | |

| CIMR-PU2A0312 | 90 | 312 | 0-6000 | reduced! | |

| CIMR-PU2A0360 | 110 | 360 | 0-6000 | reduced! | |

| CIMR-PU2A0415 | 110 | 415 | 0-6000 | reduced! | |

P1000 series for pump application (3 phase 380-480 V)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Price | |

|---|---|---|---|---|---|

| CIMR-PU4A0002 | 0,75 | 2.1 | 0-6000 | reduced! | |

| CIMR-PU4A0004 | 1,5 | 4.1 | 0-6000 | reduced! | |

| CIMR-PU4A0005 | 2,2 | 5.4 | 0-6000 | reduced! | |

| CIMR-PU4A0007 | 3 | 6.9 | 0-6000 | reduced! | |

| CIMR-PU4A0009 | 3,7 | 8.8 | 0-6000 | reduced! | |

| CIMR-PU4A0011 | 5,5 | 11.1 | 0-6000 | reduced! | |

| CIMR-PU4A0018 | 7,5 | 17.5 | 0-6000 | reduced! | |

| CIMR-PU4A0023 | 11 | 23 | 0-6000 | reduced! | |

| CIMR-PU4A0031 | 15 | 31 | 0-6000 | reduced! | |

| CIMR-PU4A0038 | 18,5 | 38 | 0-6000 | reduced! | |

| CIMR-PU4A0044 | 22 | 44 | 0-6000 | reduced! | |

| CIMR-PU4A0058 | 30 | 58 | 0-6000 | reduced! | |

| CIMR-PU4A0072 | 37 | 72 | 0-6000 | reduced! | |

| CIMR-PU4A0088 | 45 | 88 | 0-6000 | reduced! | |

| CIMR-PU4A0103 | 55 | 103 | 0-6000 | reduced! | |

| CIMR-PU4A0139 | 75 | 139 | 0-6000 | reduced! | |

| CIMR-PU4A0165 | 90 | 165 | 0-6000 | reduced! | |

| CIMR-PU4A0208 | 110 | 208 | 0-6000 | reduced! | |

| CIMR-PU4A0250 | 132 | 250 | 0-6000 | reduced! | |

| CIMR-PU4A0296 | 160 | 296 | 0-6000 | reduced! | |

| CIMR-PU4A0362 | 185 | 362 | 0-6000 | reduced! | |

| CIMR-PU4A0414 | 220 | 414 | 0-6000 | reduced! | |

| CIMR-PU4A0515 | 250 | 515 | 0-6000 | reduced! | |

| CIMR-PU4A0675 | 355 | 675 | 0-6000 | reduced! | |

Features and Benefits of Yaskawa drive P1000 series

Exceptional Quality- Enjoy peace of mind by knowing that you are considering a product from Yaskawa, the factory automation controls company with the highest reputation for quality and reliability. Historically, Yaskawa drives have demonstrated extremely high reliability with an average MTBF (mean time between failure) of 28 years or more. The new 1000 series products take reliability to the next level with a calculated design life that is twice as long as previous generations.

- Highly Integrated Design results in fewer parts and interconnections, reducing the number of failure points.

- Component Derating extends the life of any single part by selecting higher specifications (e.g., voltage, current) than what a circuit requires for normal operation.

- Latest Generation IGBT Power Modules, capable of four times more thermal cycles than previous designs.

- Enhanced Short Circuit Detection and Self Diagnostics provide additional protection against severe catastrophic conditions.

Yaskawa vfd P1000 series is Easy to Apply and Maintain

The P1000 is supported by user-friendly configuration tools. For local field access, the keypad interface features a multi-language LCD display, parameter storage, and application presets to make programming a simple task. It also has built-in memory for backup purposes. In addition, a USB Copy Unit can be loaded with a drive’s program for convenient portable transfer of configuration between an office environment and the factory floor.

Fan and Pump Application Presets

Start-up time has been reduced with preprogrammed application presets that allow for simple and easy start-up by answering simple motor and application information. Application Presets: General Purpose; Pump & Pump with PI Feedback Control; Fan & Fan with PI Feedback Control

- Online and Offline Editing

- Application Wizard

- Monitoring and Diagnostic Panels

-Trend Recorder and Playback

- Network Configurator

- Multidrive Support •Drive Flash Support

- Project Converter

- Report and Export Generation

- Search Engine

- Real Time Clock (RTC)

Take advantage of the battery-backed clock that’s built into the P1000’s keypad display. With this feature, the P1000 can be controlled based on time of day, and can also provide timestamped event information.

- PI Process Control

Two separate process control loops are embedded in the P1000. One modifies drive speed based on setpoint and sensor feedback. A second control loop (with its own setpoint and feedback inputs) can be output to control something completely independent of the drive. Additionally, the P1000 provides a 24VDC, 150mA supply for applying power to sensors.

- Selectable and User-Customizable Engineering Units

Allow for easy configuration of keypad display to match process and feedback devices such as PSI, GPM, Feet.

Preventative Maintenance Monitors

Maximize production and intelligently schedule your maintenance by making use of the P1000’s special monitors that provide alarm information when a drive requires attention. Use this information to trigger discrete outputs or send the status across a network for upper level decision making.

- Cooling Fan Remaining Life

- IGBT (Power Module) Remaining Life

- Bus Capacitor Remaining Life

- Precharge Relay

- Drive (Heatsink) Temperature

Highly Reliable and Easily Replaceable Cooling Fans

- Improved location for convenient access, even when mounted with heatsink external

- No tools required

- All ratings are 24Vdc powered

Removeable I/O Terminal Board with Drive Backup Memory

- All parameter changes automatically saved to both main control board and I/O board

- Leave I/O connected when replacing a drive

- Configuration is downloaded to replacement drive

- Reduces MTTR (Mean Time To Repair)

Underload Detection

Monitors the load and will stop the system in the event of a fan belt or pump shaft failure.

Dynamic Noise Control

Monitors the load at all times and reduces the output voltage automatically, reducing motor audible noise.

Maximum Flexibility of Yaskawa's frequency inverter P1000 series

Enjoy a significant amount of standard control points. The P1000 can also expand to support popular communication networks.

Standard I/O and Communications

- Digital Inputs (8)

- Analog Inputs (3)

- Pulse Inputs (1)

- Digital Outputs (4)

- 2 Form C Relays

- 2 Form A Relays

- Analog Outputs (2)

- RS485 Modbus RTU Communication

Expansion Capability

- Analog Output Module (3 additional outputs)

- DeviceNet • EtherNet/IP (Single and Dual Port)

- Modbus TCP/IP (Single and Dual Port)

- PROFIBUS-DP

- PROFINET

- BACnet • Lonworks

- Metasys (N2)

- Apogee (P1)

- MECHATROLINK-II

- MECHATROLINK-III

Auxiliary Control Power Input

Keep your drives communicating over the network, even while main power is removed. The Auxiliary Control Power Input uses facility supplied 24Vdc to keep the drive’s control and communication intact. Service your drive cabinets with the benefit of live control and communications without the need for main power and associated Arc Flash protection.

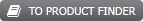

Type 12 Flange Configuration

P1000 is available in all ratings as a Type 12 Flange configuration that allows for mounting the drive with its heatsink out the back of any Type 12 enclosure. This allows for the majority of the drive’s heat to dissipate on the external side, while keeping the enclosure small and sealed with Type 12 integrity.

Trip-free Operation for Yaskawa drive P1000 series

Keep your applications running with features designed to avoid interruptions that are typical with demanding load conditions.

- Optimal Decel automatically extends the programmed deceleration time based on the load condition and drive capability.

- Overvoltage Suppression limits the DC bus voltage by modulating output frequency to keep the drive out of the regenerative region.

- Overload Fault Prevention responds to heavy load conditions by adjusting output frequency and voltage to keep the drive’s current within operating limits.

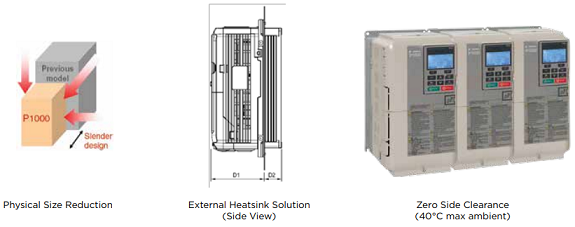

- Momentary Power Loss Ride-Thru puts the drive in standby mode during transient power losses and then automatically restarts, avoiding potentially costly power related shut down conditions.

- Bi-directional speed search allows the drive to start into a rotating load by quickly sensing the speed and direction of the motor and then seamlessly matching the drive’s output.

- For applications that can dissipate losses in the motor, Over-Excitation Braking and High Slip Braking are goodperforming, money-saving alternatives to dynamic braking.

- In the event of a power loss, Kinetic Energy Braking uses energy stored in the rotating load to keep the drive powered and bring the process to a controlled stop.

Environmental features designed into the Yaskawa frequency inverter P1000 series

Reduce your energy bill and contribute towards a cleaner environment with sustainable features designed into the P1000.

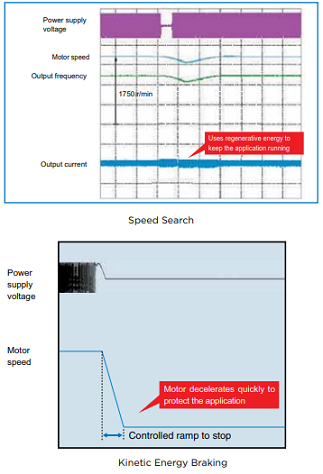

Energy Savings Benefits of Variable Speed

Using variable speed on pumps and fans results is very large energy savings as compared to other fluid or air control methods (valves, guide vanes, dampers, etc.). Additionally, the P1000 provides even greater savings with its Energy Saving Control that reduces unnecessary magnetizing current at reduced speeds.

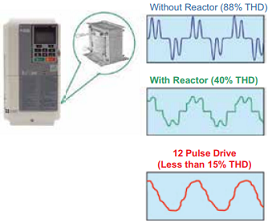

Power Quality Conscious

Built-in DC reactors (30 HP and larger) provide input harmonics benefit, and protection from input disturbances. To further reduce harmonics reflected back to the utility power line, the P1000 is available with an integrated 12-pulse diode bridge from 40 to 1000 HP @ 480VAC (also requires the use of an external phase-shifting transformer).

Product Life Cycle Responsibility

The future of our environment and the earth’s natural resources is very important to Yaskawa. The P1000 has been designed to minimize the use of harmful materials (e.g. lead, mercury, cadmium, etc.) and meets the requirements of RoHS (Restriction of Hazardous Substances)