|

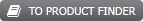

The VLT® Refrigeration Drive FC 103 covers a power range between 1.1-630 kW. It allows the user to profit from the speed control by saving energy and prolonging lifetime of essential equipment. Available in a variety of protection classes the drive suits the needs of pump, fan and compressor applications. Every application and power size can be operated and programmed with the same common user interface.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

VLT Refrigeration Drive FC 103 series, 380-480 V (3 phase), IP20, RFI Class A1/B (C1), Graphical Local Control Panel (LCP-102)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-103P1K1T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 90x246x205 | 676,00 € | |

| FC-103P1K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 90x246x205 | 775,00 € | |

| FC-103P2K2T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 90x246x205 | 936,00 € | |

| FC-103P3K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 90x246x205 | 1 044,00 € | |

| FC-103P4K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 90x246x205 | 1 115,00 € | |

| FC-103P5K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 130x246x205 | 1 290,00 € | |

| FC-103P7K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 130x246x205 | 1 450,00 € | |

| FC-103P11KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 165x350x248 | 1 869,00 € | |

| FC-103P15KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 165x350x248 | 2 112,00 € | |

| FC-103P18KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 165x350x248 | 2 631,00 € | |

| FC-103P22KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 231x460x242 | 3 070,00 € | |

| FC-103P30KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 231x460x242 | 3 569,00 € | |

| FC-103P37KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 231x460x242 | 4 305,00 € | |

| FC-103P45KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 308x490x333 | 5 258,00 € | |

| FC-103P55KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 55 | 106 | 1-3600 | 308x490x333 | 6 359,00 € | |

| FC-103P75KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 370x600x333 | 7 323,00 € | |

| FC-103P90KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 370x600x333 | 8 572,00 € | |

VLT Refrigeration Drive FC 103 series, 380-480 V (3 phase), IP20, RFI Class A2 (C3), Graphical Local Control Panel (LCP-102)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-103P1K1T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 90x246x205 | 613,00 € | |

| FC-103P1K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 90x246x205 | 704,00 € | |

| FC-103P2K2T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 90x246x205 | 848,00 € | |

| FC-103P3K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 90x246x205 | 945,00 € | |

| FC-103P4K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 90x246x205 | 1 006,00 € | |

| FC-103P5K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 130x246x205 | 1 160,00 € | |

| FC-103P7K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 130x246x205 | 1 299,00 € | |

| FC-103P11KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 165x350x248 | 1 661,00 € | |

| FC-103P15KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 165x350x248 | 1 897,00 € | |

| FC-103P18KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 165x350x248 | 2 386,00 € | |

| FC-103P22KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 231x460x242 | 2 794,00 € | |

| FC-103P30KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 231x460x242 | 3 250,00 € | |

| FC-103P37KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 231x460x242 | 3 978,00 € | |

| FC-103P45KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 308x490x333 | 4 867,00 € | |

| FC-103P55KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 55 | 106 | 1-3600 | 308x490x333 | 5 831,00 € | |

| FC-103P75KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 370x600x333 | 6 624,00 € | |

| FC-103P90KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 370x600x333 | 7 792,00 € | |

| FC-103N110T4E20H2XGCXXXSXXXXAXBXCXXXXDX | 110 | 212 | 1-3600 | 909x325x378 | 8 008,00 € | |

| FC-103N132T4E20H2XGCXXXSXXXXAXBXCXXXXDX | 132 | 260 | 1-3600 | 909x325x378 | 9 670,00 € | |

| FC-103N160T4E20H2XGCXXXSXXXXAXBXCXXXXDX | 160 | 315 | 1-3600 | 909x325x378 | 11 808,00 € | |

| FC-103N200T4E20H2XGCXXXSXXXXAXBXCXXXXDX | 200 | 395 | 1-3600 | 1122x350x375 | 14 099,00 € | |

| FC-103N250T4E20H2XGCXXXSXXXXAXBXCXXXXDX | 250 | 480 | 1-3600 | 1122x350x375 | 18 075,00 € | |

| FC-103N315T4E20H2XGCXXXSXXXXAXBXCXXXXDX | 315 | 600 | 1-3600 | 1122x350x375 | 21 753,00 € | |

VLT Refrigeration Drive FC 103 series, 380-480 V (3 phase), IP55, RFI Class A1/B (C1), Graphical Local Control Panel (LCP-102)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-103P1K1T4Z55H1XGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 390x200x175 | 794,00 € | |

| FC-103P1K5T4Z55H1XGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 390x200x175 | 893,00 € | |

| FC-103P2K2T4Z55H1XGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 390x200x175 | 1 054,00 € | |

| FC-103P3K0T4Z55H1XGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 390x200x175 | 1 162,00 € | |

| FC-103P4K0T4Z55H1XGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 390x200x175 | 1 232,00 € | |

| FC-103P5K5T4P55H1XGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 420x242x200 | 1 422,00 € | |

| FC-103P7K5T4P55H1XGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 420x242x200 | 1 582,00 € | |

| FC-103P11KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 480x242x260 | 2 086,00 € | |

| FC-103P15KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 480x242x260 | 2 361,00 € | |

| FC-103P18KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 480x242x260 | 2 940,00 € | |

| FC-103P22KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 650x242x260 | 3 433,00 € | |

| FC-103P30KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 650x242x260 | 3 989,00 € | |

| FC-103P37KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 680x308x310 | 4 737,00 € | |

| FC-103P45KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 680x308x310 | 5 782,00 € | |

| FC-103P55KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 55 | 106 | 1-3600 | 680x308x310 | 6 983,00 € | |

| FC-103P75KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 770x370x335 | 8 031,00 € | |

| FC-103P90KT4P55H1XGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 770x370x335 | 9 381,00 € | |

VLT Refrigeration Drive FC 103 series, 380-480 V (3 phase), IP55, RFI Class A2 (C3), Graphical Local Control Panel (LCP-102)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-103P1K1T4Z55H2XGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 390x200x175 | 730,00 € | |

| FC-103P1K5T4Z55H2XGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 390x200x175 | 821,00 € | |

| FC-103P2K2T4Z55H2XGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 390x200x175 | 967,00 € | |

| FC-103P3K0T4Z55H2XGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 390x200x175 | 1 062,00 € | |

| FC-103P4K0T4Z55H2XGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 390x200x175 | 1 123,00 € | |

| FC-103P5K5T4P55H2XGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 420x242x200 | 1 291,00 € | |

| FC-103P7K5T4P55H2XGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 420x242x200 | 1 431,00 € | |

| FC-103P11KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 480x242x260 | 1 878,00 € | |

| FC-103P15KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 480x242x260 | 2 146,00 € | |

| FC-103P18KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 480x242x260 | 2 695,00 € | |

| FC-103P22KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 650x242x260 | 3 157,00 € | |

| FC-103P30KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 650x242x260 | 3 670,00 € | |

| FC-103P37KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 680x308x310 | 4 409,00 € | |

| FC-103P45KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 680x308x310 | 5 392,00 € | |

| FC-103P55KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 55 | 75 | 1-3600 | 680x308x310 | 6 456,00 € | |

| FC-103P75KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 770x370x335 | 7 333,00 € | |

| FC-103P90KT4P55H2XGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 770x370x335 | 8 601,00 € | |

VLT Refrigeration Drive FC 103 series, 380-480 V (3 phase), IP54, RFI Class A2 (C3), Graphical Local Control Panel (LCP-102)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-103N110T4E54H2XGCXXXSXXXXAXBXCXXXXDX | 110 | 212 | 1-3600 | 901x325x378 | 9 040,00 € | |

| FC-103N132T4E54H2XGCXXXSXXXXAXBXCXXXXDX | 132 | 260 | 1-3600 | 901x325x378 | 10 918,00 € | |

| FC-103N160T4E54H2XGCXXXSXXXXAXBXCXXXXDX | 160 | 315 | 1-3600 | 901x325x378 | 13 337,00 € | |

| FC-103N200T4E54H2XGCXXXSXXXXAXBXCXXXXDX | 200 | 395 | 1-3600 | 1060x420x378 | 15 927,00 € | |

| FC-103N250T4E54H2XGCXXXSXXXXAXBXCXXXXDX | 250 | 480 | 1-3600 | 1060x420x378 | 20 258,00 € | |

| FC-103N315T4E54H2XGCXXXSXXXXAXBXCXXXXDX | 315 | 600 | 1-3600 | 1060x420x378 | 24 381,00 € | |

Danfoss VLT Refrigeration Drive FC 103 improves efficiency of compressors, condensers, evaporators and pumps

Reducing the operating costs of refrigeration systems with quick payback is becoming increasingly important. Speed control of the electric drives used in these systems is a pragmatic and effective approach. Load-dependent speed control reduces power consumption and therefore saves money. When you consider that energy costs amount to 90% or more of total operating costs over the total product lifetime, it’s easy to see that there is plenty of potential for savings in this area. Speed control also lowers mechanical stress in the system, which reduces service and maintenance costs.

Danfoss VLT® Refrigeration vfd FC 103 – simply uncomplicated

Danfoss developed the VLT® Refrigeration Drive FC 103 to allow all users in the refrigeration world to benefit from the advantages of speed control in a simple, uncomplicated manner. With its functions specifically tailored for refrigeration technology, it reduces total life cycle costs in the application. The drive reduces the number of external components, required integrates easily into existing refrigeration systems, and makes motors energy efficient thanks to its high performance. In this way it improves the energy balance of the overall refrigeration system and reduces its environmental footprint.

Optimise compressor performance coefficient – Achieve system-wide energy efficiency

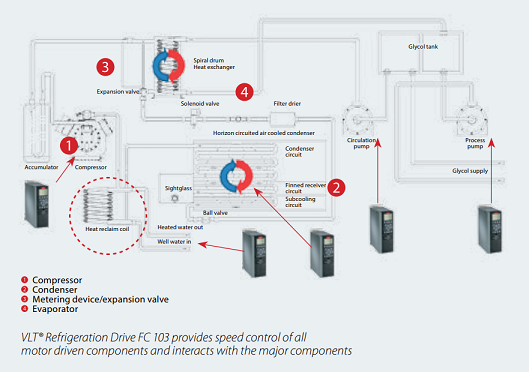

The performance of a refrigeration system is expressed using the energy efficiency ratio (EER) or the coefficient of performance (COP). This is the ratio of the generated cooling or heating capacity to the power actually consumed, and is usually based on full-load operation. However, it is not enough to rate a refrigeration unit at just one load level, since most refrigeration systems operate under partial load conditions. This means that significant energy savings can be obtained using speed control.

Danfoss VLT Refrigeration frequency inverter FC 103 Refrigeration system without speed control

In a refrigeration system without speed control, the compressor always runs at full speed, regardless of the cooling capacity actually required. The cooling output is regulated by the evaporator, which is filled by the expansion device. Since the expansion valve constantly tries to fill the evaporator optimally, this adjustment causes the evaporation pressure to change and therefore creates oscillation in the system. With the compressor operating at full output capacity, this oscillation can persist for a very long time. As a result, the evaporator is never properly filled and operates ineffectively, and the cooling capacity of the refrigerant is not optimal.

Refrigeration system with speed control

The continuous variable speed control by VLT® Refrigeration Drive FC 103 makes intelligent capacity control possible. By creating stability while balancing the capacity to the actual load, system-wide COP improves providing significant energy savings. Intelligent compressor and condenser fan control is a “must” in any optimised refrigeration system. The following positive effects can be achieved in a refrigeration system with variable-speed compressor operation:

Compressor

- 6 compressors pack controller

- Stable suction pressure

- Increased capacity using a smaller compressor

- Built-in soft starter function

- Built-in oil return management improves reliability and lifetime

- Low and high pressure monitoring

- Reduced mechanical load

- Fewer start and stops extends the lifetime

- No mechanical capacity control

- Improves system COP

Condenser fan control

- Load dependent capacity control

- Operate single fans/multiple parallel operating fans

- Stable condensing pressure

- Floating condensing temperature adapts to outdoor temperature

- Reduced charge of refrigerant

- Less dirt build-up on condenser

- Stand-alone control using VLT® Refrigeration Drive FC 103

- Improves system COP

Pumps in process cooling or air-conditioning systems

-Coolant pump capacity according to demand

- Stable coolant flow and pressure

- Stand-alone control using VLT® Refrigeration Drive FC 103

- Operate from direct signal (0/4-20 mA or 0-10 V DC)

Fans in process cooling or airconditioning systems

- Optimized operation of air handling units

- High efficiency

- Airflow according to demand

- Stand-alone control using VLT® Refrigeration Drive FC 103

- Operate from direct signal (0/4-20 mA or 0-10 V DC)

Depending on the application, speed control can result in energy savings ranging from 10% to as much as 70%.

Danfoss VLT Refrigeration inverter FC 103 has a Multi-zone pack controller – Improved energy savings and stable operation

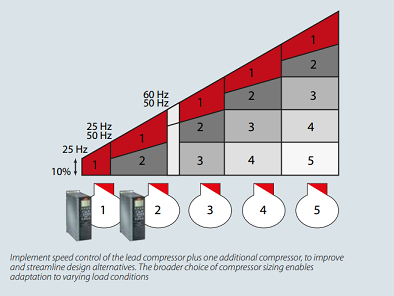

There is a speed range in the interaction between the compressor and frequency converter that allows the system to save energy. The compressor should function within this range most of the time. If the difference between the maximum required performance and the average performance under partial load is too great, it is a good idea to use a cascade configuration. In many cases the required capital investment, including the conversion of an existing system, will be amortised quickly.

Cascading the system

In a system with cascaded compressors, the base load is handled by a speed-controlled compressor. If the demand rises, the drive starts up additional compressors one at a time. As a result, the compressors work largely at their optimum efficiency point, with the control constantly ensuring that the system is operating at maximum energy efficiency. Step-less capacity control thus achieved eliminates the need for large number of small size compressors. This cascading principle can also be applied to fans and pumps using the VLT® Refrigeration Drive FC 103.

Danfoss VLT Refrigeration Drive FC 103 has a Advanced Multi-zone pack controller

- Effectively cascades and controls up to 6 compressors pack- Focused towards piston, screw and scroll compressors

- Three zone setups avoid too frequent staging and de-staging

- Makes pressures & temperatures stable.

- Reduces compressor wear & tear

- Can also control groups of condenser fans

Easy commissioning

The VLT® Refrigeration FC 103 drive offers a setup wizard, using common refrigeration terms rather than computer language. Field testing shows that ease of programming makes installers and service technicians more comfortable and confident, making their jobs easier and quicker. The wizard menu also supports the commissioning engineers if they encounter any problems. The menu will help the engineer troubleshoot and offer ‘quick fixes’ to get the drive up and running if there is a problem.

Commissioning is fast and easy using the the frequency converter display panel. The wizard that appears the first time the device is switched on guides the user through the necessary settings. The user only has to switch from external to internal control. If necessary, the wizard can be called up again from the Quick Menu. Configuring the necessary parameters is even easier with the wizard in theVLT® Motion Control Tool MCT 10 software. During operations, the FC 103 can show the compressor status on the frequency converter display panel and log the compressor’s operating time and number of starts.

Reduced service costs

Mechanical wear is automatically reduced by the fact that only as many compressors are running as are actually needed. This allows service intervals to be extended. The user can configure rotation of mains-powered compressors to ensure that they all end up with a similar number of operating hours.

Danfoss VLT Refrigeration vfd FC 103 dedicated compressor features

The VLT® Refrigeration Drive FC 103 is designed for operating piston, scroll, screw compressors and centrifugal compressors. Variable speed control allows the refrigeration capacity of a compressor to be adapted to exactly match the demand.

Day/night control

Compressors usually operate with different setpoints depending on the time of day. This in turn results in different evaporator fan speeds, resulting in reduced energy consumption. This function can be easily programmed with day/night control.

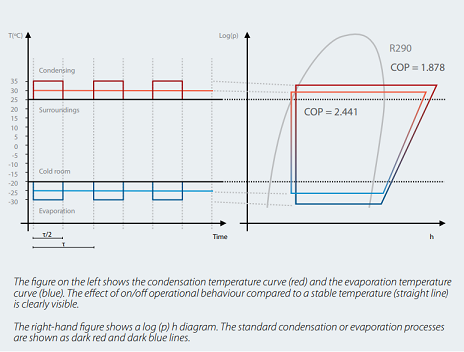

Neutral Zone

The FC 103 continues to control fixed speed compressors in situations where the variable speed compressor fails. Neutral zone is in a fail situation set by a special parameter ”Fixed speed neutral zone”. This gives the opportunity to have fewer starts by expanding the neutral zone and longer duration of safe operation even under challenging situations.

Oil Return Management

If compressors run at low speed for longer periods of time, lubrication oil will end up in the refrigerant and pipelines. Lack of oil in crankcase causes insufficient lubrication. Built-in oil return management in the FC 103 ensures oil is returned to crankcase thus significantly improving system reliability. Oil management functionality increases the compressor speed up to its maximum value for the user defined interval of time and brings the oil back to the compressor.

- Oil boost functionality activates at fixed time intervals

- Or when the compressor speed has been lower than nominal speed for too long time

- Improves lubrication and system reliability

Condensing temperature monitoring

The frequency converter can monitor the Floating Head Pressure high pressure levels using connected temperature sensors. Speed is reduced before the head pressure reaches a critical value. This allows safe operation of system for longer duration thus enhancing food safety and process control.

Single compressor or pack

The user has the choice of operating the system with a single large compressor or using the pack controller to operate the system with several smaller compressors which are activated as the demand for cooling capacity increases. The built in Pack Controller can distribute running hours evenly across all compressors, keeping wear and tear on individual compressors to a minimum and ensures that all compressors are in great shape.

Direct entry of evaporator temperature

The user can enter the desired evaporator temperature directly in the control panel of the FC 103. The frequency converter also takes the properties of the refrigerant into account. Tables for the most commonly used refrigerants are preloaded in the frequency converter. User-defined entry of the refrigerant used in the system is also possible. Simplifies commissioning.

Inject ON

When all connected compressors on the FC 103 are stopped due to a missing safety circuit, this will be registered by the system unit which will close all valves connected to the case controllers. This supports prevention of liquid flow to the compressor when FC 103 starts the compressor again. As soon as a compressor starts running again, the valves will reopen.

Fewer starts and stops

Start-up is the critical phase of compressor operation. The FC 103 minimises the number of required starts and stops by varying the speed of the compressor to match the capacity to the cooling demand. This ensures maximum run time and minimum number of starts and stops. In addition, the maximum number of start/stop cycles in a given period can be configured using the control panel.

To further extend the lifetime of the FC 103 a pressure relief valve can be opened to allow the compressor to start up quickly with no load. 135% Starting torque

The FC 103 delivers 135% of the rated starting torque for a period of half a second. In normal operation, 110% of the rated torque is available for 60 seconds.

Smaller compressors with the same peak load

The operator can configure the system with a smaller compressor for a given peak load. This provided that the compressor is designed for over-speed operation, the FC 103 can run it at up to 90 Hz. This may allow brief peak loads to be handled in this way without necessarily requiring a larger compressor for this purpose.

P0 optimisation

The FC 103 supports connection of an ADAP-KOOL® LonWorks control for P0 optimisation.

Danfoss VLT Refrigeration drive FC 103 dedicated condenser and evaporator features

User-friendly, distributed intelligence and reduced power consumption are beneficial for condenser and evaporator applications.

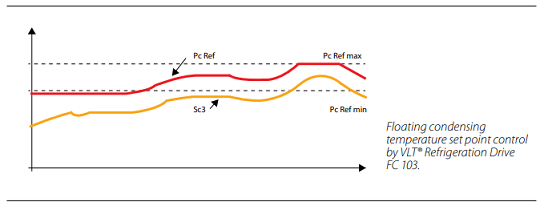

Floating condensing temperature optimises COP VLT®

Refrigeration Drive FC 103 intelligently controls evaporative condensers or air-cooled condensers to optimise refrigeration system performance (COP) at lower energy consumption. The drive adapts condensing temperature set point as the outdoor temperature drops, lowering the set point to a new stable level. This functionality provides:

- Increased cooling capacity at lower power consumption

- Ability to run on fewer compressors, hence reducing wear and tear

Intelligent functions

The FC 103 handles logical rules and inputs from sensors, real time functionality and time-related actions. This enables the FC 103 to control a wide range of functions, including: • Weekend and working-day operations

- Cascaded P-PI for temperature control

- Belt monitoring

Resonance monitoring

By pressing a few buttons on the Local Control Panel, the drive can be set to avoid frequency bands, at which connected fans create resonances in the in condensers or evaporators. This reduces vibration noise and wear and tear on equipment

Auto tuning of the PI controllers

With auto tuning of the PI controllers, the drive monitors how the system reacts on corrections made by the drive – and learns from it.

Extended I/O capacity

When operated by an external controller, all the FC 103 I/O points are available as remote I/O to extend the capacity of the controller. For example, room temperature sensors (Pt1000/ Ni1000) can be directly connected.

Danfoss VLT Refrigeration frequency inverter FC 103 4 x PID controller (Individual set-points/feed-backs)

- PID for closed loop control of the motor connected to the drive- 3 PIDs for external closed loop control of refrigeration equipment

- Auto-tuning of all 4 PID loops

- Eliminates the need for other controllers

- Provides flexibility for the controller and reduces the load

Protect people and equipment

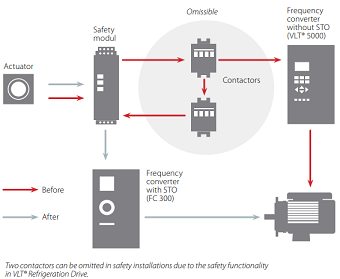

To protect people and equipment, in practically all refrigeration applications, the system operator must ensure that compressors are actually stopped and cannot start up again. This is important in order to avoid HP tripping or vacuum formation in the suction line or the evaporator. The Safe Torque Off function (compliant with EN 61800-5-2) of the VLT® Refrigeration Drive FC 103 provides a cost-effective way to implement this with high reliability. Unlike software functions that trigger a stop command using the digital inputs, here the control voltage of the output module is enabled or disabled directly via the safe terminal of the frequency converter. This reduces cabling cost, and the functionality integrated in the FC 103 eliminates the need for costly and bulky external components, such as contactors and relays, that are used for this purpose in conventional solutions.

Easy commissioning

Another significant advantage of the integrated safety function in the FC 103 is that it can be activated without special software or complicated set-up procedures. This considerably simplifies commissioning, servicing, and the replacement of individual components.

Simplified installation

VLT® Refrigeration Drive FC 103 eliminates the need for special start equipment due to built-in current reduction. It offers motor protection against overload and high temperature conditions and has built-in crank case heater functionality.

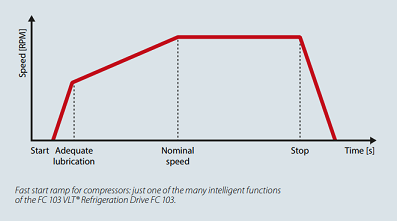

Start up compressors gently and reduce wear and tear

There is often insufficient lubrication when compressors are started or operated at excessively low speeds. This is not a problem when compressors are started directly from the mains, since they pass through the critical area quickly. However, in theory the situation is different with variable speed operation: long ramp times mean slow acceleration, resulting in extended operation in the critical region. To effectively avoid this potential source of wear, the FC 103 provides a separate start ramp for the start-up process when working with a compressor. Once the compressor has passed through the critical region and adequate lubrication is assured, it automatically switches to a slower and gentler starting ramp. Naturally, the fast ramp is also active during the stop process.

Product code list with corresponding models for

Danfoss frequency inverters VLT Refrigeration Drive FC 103 series

| Item code | Model name |

| 134F7620 | FC-103P1K1T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7621 | FC-103P1K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7622 | FC-103P2K2T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7623 | FC-103P3K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7624 | FC-103P4K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7625 | FC-103P5K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7626 | FC-103P7K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7627 | FC-103P11KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7628 | FC-103P15KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7629 | FC-103P18KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7630 | FC-103P22KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7631 | FC-103P30KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7632 | FC-103P37KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7633 | FC-103P45KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7634 | FC-103P55KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7635 | FC-103P75KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7636 | FC-103P90KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F8181 | FC-103P1K1T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8182 | FC-103P1K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8183 | FC-103P2K2T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8184 | FC-103P3K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8185 | FC-103P4K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8186 | FC-103P5K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8187 | FC-103P7K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8188 | FC-103P11KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8189 | FC-103P15KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8190 | FC-103P18KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8056 | FC-103P22KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8055 | FC-103P30KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8054 | FC-103P37KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8052 | FC-103P45KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8191 | FC-103P55KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8053 | FC-103P75KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8192 | FC-103P90KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 134G0750 | FC-103P1K1T4Z55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134G0751 | FC-103P1K5T4Z55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134G0752 | FC-103P2K2T4Z55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134G0801 | FC-103P3K0T4Z55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134G0753 | FC-103P4K0T4Z55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7665 | FC-103P5K5T4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7663 | FC-103P7K5T4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7676 | FC-103P11KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7489 | FC-103P15KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7677 | FC-103P18KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7678 | FC-103P22KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7679 | FC-103P30KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7680 | FC-103P37KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7681 | FC-103P45KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7682 | FC-103P55KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7684 | FC-103P75KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134F7685 | FC-103P90KT4P55H1XGXXXXSXXXXAXBXCXXXXDX |

| 134H3445 | FC-103P1K1T4Z55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134H3446 | FC-103P1K5T4Z55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134H3447 | FC-103P2K2T4Z55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134H3448 | FC-103P3K0T4Z55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134H3449 | FC-103P4K0T4Z55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8977 | FC-103P5K5T4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8978 | FC-103P7K5T4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8979 | FC-103P11KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8980 | FC-103P15KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8981 | FC-103P18KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8982 | FC-103P22KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8983 | FC-103P30KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8984 | FC-103P37KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F7781 | FC-103P45KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8985 | FC-103P55KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8986 | FC-103P75KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134F8987 | FC-103P90KT4P55H2XGXXXXSXXXXAXBXCXXXXDX |

| 134H1341 | FC-103N110T4E20H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1342 | FC-103N132T4E20H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1343 | FC-103N160T4E20H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1344 | FC-103N200T4E20H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1345 | FC-103N250T4E20H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1346 | FC-103N315T4E20H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1274 | FC-103N110T4E54H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1275 | FC-103N132T4E54H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H3492 | FC-103N160T4E54H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H2091 | FC-103N200T4E54H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H1086 | FC-103N250T4E54H2XGCXXXSXXXXAXBXCXXXXDX |

| 134H2092 | FC-103N315T4E54H2XGCXXXSXXXXAXBXCXXXXDX |

Download manuals (all parameters)

Danfoss frequency converters (changers)