|

SINAMICS G180 are compact devices, cabinet systems and cabinet units (air and liquid cooled) for variable-speed drives in plant and machinery construction; which have been specifically designed for applications in oil and gas, the chemical and process industries. They have been specially developed to address the requirements of drives with square law and constant load characteristics. SINAMICS G180 represents the optimum drive solution that can be adapted to the various sector-specific requirements in the core sectors using a wide range of options and X options (special, customer-specific options). SINAMICS G180 can be flexibly integrated into any automation concept, either using conventional control or via a bus system.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads  Request additional information and get a price quote Request additional information and get a price quote |

Model range

SINAMICS G180 industrial series / compact unit ( 3 phase 380-480 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| 6SE0100-1AC15-5_A7 | 2,2 | 5.5 | 165x410x320 | reduced! | |

| 6SE0100-1AC17-0_A7 | 3 | 7 | 165x410x320 | reduced! | |

| 6SE0100-1AC21-0_A7 | 4 | 9.5 | 165x410x320 | reduced! | |

| 6SE0100-1AC21-3_A7 | 5,5 | 13 | 165x410x320 | reduced! | |

| 6SE0100-1AC21-8_A7 | 7,5 | 18 | 165x510x320 | reduced! | |

| 6SE0100-1AC22-5_A7 | 11 | 24.5 | 165x510x320 | reduced! | |

| 6SE0100-1AC23-7_A7 | 15 | 37 | 225x610x320 | reduced! | |

| 6SE0100-1AC24-8_A7 | 22 | 48 | 225x610x320 | reduced! | |

| 6SE0100-1AC25-8_A7 | 30 | 58 | 225x610x320 | reduced! | |

| 6SE0100-1AC27-8_A7 | 37 | 78 | 350x710x320 | reduced! | |

| 6SE0100-1AC28-8_A7 | 45 | 88 | 350x710x320 | reduced! | |

| 6SE0100-1AC31-1_A7 | 55 | 110 | 350x710x320 | reduced! | |

| 6SE0100-1AC31-5_A7 | 75 | 145 | 350x1060x320 | reduced! | |

| 6SE0100-1AC31-8_A7 | 90 | 175 | 350x1060x320 | reduced! | |

| 6SE0100-1AC32-1_A7 | 110 | 205 | 350x1060x320 | reduced! | |

| 6SE0100-1AC32-5_A7 | 132 | 245 | 500x1060x320 | reduced! | |

| 6SE0100-1AC33-0_A7 | 160 | 295 | 500x1060x320 | reduced! | |

SINAMICS G180 industrial series / compact unit ( 3 phase 480-500 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| 6SE0100-1AD14-5_A7 | 2,2 | 4.5 | 165x410x320 | reduced! | |

| 6SE0100-1AD15-5_A7 | 3 | 5.5 | 165x410x320 | reduced! | |

| 6SE0100-1AD17-0_A7 | 4 | 7 | 165x410x320 | reduced! | |

| 6SE0100-1AD21-0_A7 | 5,5 | 9.5 | 165x410x320 | reduced! | |

| 6SE0100-1AD21-3_A7 | 7,5 | 13 | 165x410x320 | reduced! | |

| 6SE0100-1AD21-8_A7 | 11 | 18 | 165x510x320 | reduced! | |

| 6SE0100-1AD22-5_A7 | 15 | 24.5 | 165x510x320 | reduced! | |

| 6SE0100-1AD23-7_A7 | 22 | 37 | 225x610x320 | reduced! | |

| 6SE0100-1AD24-8_A7 | 30 | 48 | 225x610x320 | reduced! | |

| 6SE0100-1AD25-8_A7 | 37 | 58 | 225x610x320 | reduced! | |

| 6SE0100-1AD27-8_A7 | 45 | 78 | 350x710x320 | reduced! | |

| 6SE0100-1AD28-8_A7 | 55 | 88 | 350x710x320 | reduced! | |

| 6SE0100-1AD31-1_A7 | 75 | 110 | 350x710x320 | reduced! | |

| 6SE0100-1AD31-5_A7 | 90 | 145 | 350x1060x320 | reduced! | |

| 6SE0100-1AD31-8_A7 | 110 | 175 | 350x1060x320 | reduced! | |

| 6SE0100-1AD32-1_A7 | 132 | 205 | 350x1060x320 | reduced! | |

| 6SE0100-1AD32-5_A7 | 160 | 245 | 500x1060x320 | reduced! | |

| 6SE0100-1AD33-0_A7 | 200 | 295 | 500x1060x320 | reduced! | |

Siemens frequency inverter SINAMICS G180 series: first choice for all drive applications.

SINAMICS offers the optimum drive for every application. All members of this comprehensive system family can be configured, parameterized, commissioned and operated in the same standard way.

SINAMICS – the drive family at a glance:

- Can address each and every application: wide range power ratings from 0.12 kW to 120 MW

- Available in low-voltage and medium-voltage versions

- Standard and unified functionality as a result of the common hardware and software platform

- Standard engineering using only two tools for all drives: SIZER for engineering and STARTER (or IMS for G180) for parameterizing and commissioning

- High degree of flexibility and combinability

The experts when it comes to explosion-protected drives.

Danger of explosion, aggressive atmospheres or extreme temperatures: Drive technology in the chemical industry must fulfill the highest safety demands in order to protect man, the environment and the equipment. SINAMICS G180 represents a comprehensive drive portfolio that is designed for the widest range of applications.

Maximum safety and the highest productivity.

Whether low-voltage variable-speed drive with inverter up to 690V from 2.2 kW up to 6600 KW as standard product – or customized special solution including industrial switchgear for drive applications: Your requirements define our solution. Based on our products and systems, you create an efficient basis for your plant or system to achieve maximum safety, reliability and the highest degree of productivity. When all is said and done, our energy-efficient drive systems help to significantly reduce your operating costs. You can completely depend on us: whenever important requirements regarding explosion protection are placed on drive systems. We look after the complete drive package. Our inverters are designed to feed explosion-protected motors with types of protection EEx n, EEx e, EEx p and EEx d, and with the PTC thermistor evaluation, are certified according to ATEX. The thermal motor protection is realized using temperature sensors, which are directly evaluated in the inverter. As a result of the ATEX-certified PTC thermistor input at the inverter, no additional accessories are required, such as main contactor or PTC relay.

We are there to help and support you.

We can answer all of your questions – for instance:

- What is the correct inverter clock cycle frequency?

- What is the maximum permissible terminal voltage in the motor terminal box?

- What voltage peaks does the motor see when long motor cables are used?

- What winding insulation must the motor have?

- Mush winding or preformed winding?

- Should the motor be protected using PTC and/or PT100?

- etc.

The optimum solution for you with Siemens drive SINAMICS G180 series.

Our strengths, your advantages.

- Especially quiet and compact through the use of state-of-the-art IGBT power semiconductors and an innovative cooling concept

- System losses are minimized through the optimized clock cycle frequency

- Additional motor noise is significantly reduced through the “Random Pattern” function

- Plant and system availability is increased through power components that can be quickly and simply replaced

- User-friendly “SparesOnWeb” Internet tool that can be used to call up spare parts for any particular inverter worldwide at any time, ensuring a reliable supply of spare parts

- Minimum cabinet dimensions through optimized use of components

- Can be simply integrated into all automation solutions using analog and digital interfaces, which can be additionally expanded using an I/O board

- Seamless data transfer via the established bus systems (PROFIBUS DP, CANopen or Modbus RTU bzw. Modbus TCP)

- Short, straightforward commissioning and parameterization, menu-prompted at an operator panel with lit, graphics-capable LCD display and plain text display or PC-supported using the free-of-charge IMS commissioning tool (Inverter Management Software).

- Quality management according to DIN EN ISO 9001

- SINAMICS G180 fulfills the highest quality demands. Comprehensive quality assurance measures in all development and production processes secures a consistently high level of quality. It goes without saying that our quality management system has been certified by an independent body according to DIN EN ISO 9001.

SINAMICS G180 applications.

- Chemical Industries

- Oil and gas industries

- Power stations and utilities

- Petrochemical

- Basic materials industry

- Test stands

- Conveyor technology

- Applications in general plant and machinery construction.

Simple commissioning software for the complete series of Siemens vfd SINAMICS G180.

All of the SINAMICS G180 versions are based on a standard platform concept. Common hardware and software components as well as standard tools for dimensioning, engineering and commissioning guarantee a high degree of uniformity and standardization between all of the components. SINAMICS G180 have the same properties with identical possibilities.

Terminal strip in compliance with NAMUR Recommendation NE37.

Already in the basic versions, SINAMICS G180 units fulfill the terminal designation specifications according to NAMUR, Edition 2010, and are therefore ideally suited for use in the chemical industry.

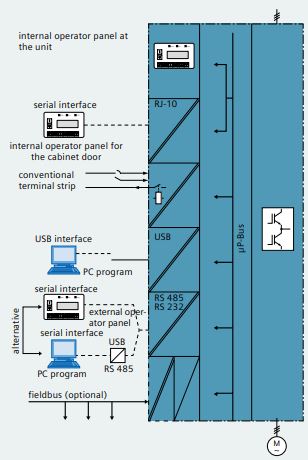

Well thought-out communications.

Communication via conventional terminal strip with freely programmable digital and analog inputs/outputs:

- Parameterizable limit value signals

- Parameterizable timers

- Parameterizable damping elements

- Parameterizable inverter behavior when inputs/outputs respond

- Parameterizable logic elements

- Communication and parameterization via PC using IMS (Inverter Management Software) via USB interface

- External operator panel via RS485 bus systems such as Ethernet (PROFIBUS board with Ethernet – PROFIBUS converter.

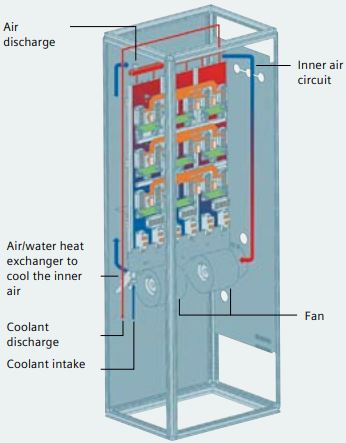

Siemens frequency inverter SINAMICS G180 series is optimally installed – also with liquid cooling.

When compared to air cooling, water cooling offers numerous advantages. This is reflected in the trend to watercooled motors and inverters. In the past, water cooling was restricted, with only some exceptions, to motors. In the meantime, it is being increasingly used for inverters. Decisive factors: The possibility of realizing increasingly larger power ratings, space-saving and the fact that it is simpler to dissipate the heat from the electrical room.

Coolant flows directly through the power unit heat sinks. The complete assembly comprises one or several aluminum cooling plates, in which stainless steel pipes are embedded. The power range extends from 200 kW up to 6,600 KW.

- Heat can be easily dissipated from the electrical room

- High cabinet degrees of protection can be implemented

- Therefore allowing installation in polluted environments

- Lower noise level

- The efficiency can be increased through heat recovery.

The solenoid valve integrated in the inverter (-Y1) controls the coolant dependent on the temperature of the ambient air, therefore effectively protecting the inverter against condensation.