|

Born out of Omron’s know-how and experience within the lift market, the LX can control gearless or geared systems. Designed for more than 5 million starts at 150% output current, the LX offers the high quality standards that you have come to expect, including noiseless operation and efficient motor control. The built-in clock & calendar and programming functionality offers flexibility in your application control.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

| Model | Capacity, kW | Current, А | Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| 3G3LX-A4037-E | 3,7 | 9 | 0-3600 | 150x255x140 | reduced! | |

| 3G3LX-A4040-E | 4 | 11 | 0-3600 | 210x260x170 | reduced! | |

| 3G3LX-A4055-E | 5,5 | 14 | 0-3600 | 210x260x170 | reduced! | |

| 3G3LX-A4075-E | 7,5 | 19 | 0-3600 | 210x260x170 | reduced! | |

| 3G3LX-A4110-E | 11 | 27 | 0-3600 | 210x260x170 | reduced! | |

| 3G3LX-A4150-E | 15 | 34 | 0-3600 | 250x390x190 | reduced! | |

| 3G3LX-A4185-E | 18,5 | 41 | 0-3600 | 250x390x190 | reduced! | |

Omron frequency inverter LX series is built from experience

Born out of Omron’s know-how and experience within the lift market, the LX can control gearless or geared systems. Designed for more than 5 million starts at 150% output current, the LX offers the high quality standards that you have come to expect, including noiseless operation and efficient motor control. The built-in clock & calendar and programming functionality offers flexibility in your application control.

Standard LCD operator display

- Designed for easy editing and access to parameters

- Copy function: for parameter settings and programming backup

- 4 configurable multi-monitor parameters with real units

- Password protection

- 10 languages available as standard: English, German, French, Spanish, Italian, Portuguese, Japanese, Chinese, Turkish and Russian

- Real time clock and calendar can save fault history with date and hour

LX inverter features

- Current vector control with or without PG

- High starting torque (200%/ 0.3 Hz sensorless vector, 200%/ 0 Hz closed loop vector control)

- Safety embedded: IEC 61508 SIL2 STO

- Lift language (Hz, m/s, rpm…)

- RS485 communication built-in –Modbus RTU–

- CE, cULus, RoHS

Motor flexibility and efficient control

- Geared induction motor control

- Gearless permanent magnet motor control

- Easy tuning and fast startup. Patented high accuracy static tuning and rotary auto-tuning

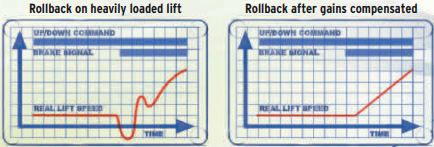

- 8 times faster control loop from previous solution, ensuring quick response against rollback

Silent and optimum operation

- No electric noise in the motor

- Fan is switched on/off depending on inverter temperature reducing audible noise

- The highest energy efficiency with PM motors

- Power supply can be cycled every 3 minutes for energy saving

Dedicated lift functionality

- Full lift sequence • Sink and source control wiring to adapt to any lift controller

- Weight sensor compensation

- Special lift sequence errors

- Anti-rollback function

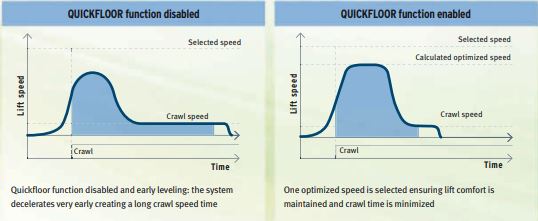

- Short floor lift travel: the Quick Floor Function reduces the time for short floor lengths

Omron vfd LX series is born to drive lifts

Advanced, dedicated lift features include: high accuracy static tuning, full lift sequence, anti-rollback function, quick floor function, emergency rescue operation, floor positioning autolearning function and Drive Programming. Experience true lift comfort with the LX inverter.

Ride comfort

- 6 s-ramp settings

- Ramps and speed auto association

- Torque ripple suppression

- Inertia compensation

- Special anti-rollback setting

Emergency rescue functionality

- Takes the passengers to floor immediately at the emergency speed

- The inverter decides the direction for minimum power

Position control

- Full positioning mode (Total floor control)

- Relative positioning mode (Floor approach mode)

- Control by digital inputs or user Drive Programming function

- Closed loop control and position control feedback independent

- Floor position auto-learning function of up to 40 floors

Built-in programming

- Drive Programming functionality for decentralized control

- Full access to parameters and inverter functions

- Flow chart and text editor programming languages

- 5 tasks running in parallel with up to 1000 lines per program

- Access to LCD real time clock