|

SINAMICS S120 modular motion control drives are designed for high performance drive applications in mechanical and systems engineering. With Siemens high performance drive capabilities, you get a range of coordinated components and functions as a complete motion control drives package. Our motion control drives include high-performance single drives and coordinated drives (multiple-axis applications) with vector or servo functionalities hat allow implementation of customized high performance drive solutions.With SINAMICS S120 motion control drives, you get a high performance drive that is flexible and increases productivity.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

SINAMICS S120 general industrial series / without EMC filter (1 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| 6SL3210-1SB11-0UA0 | 0,12 | 0.9 | 73х173х145 | reduced! | |

| 6SL3210-1SB12-3UA0 | 0,37 | 2.3 | 73х173х145 | reduced! | |

| 6SL3210-1SB14-0UA0 | 0,75 | 3.9 | 73х173х145 | reduced! | |

SINAMICS S120 general industrial series / with EMC filter (1 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| 6SL3210-1SB11-0AA0 | 0,12 | 0.9 | 73х173х145 | reduced! | |

| 6SL3210-1SB12-3AA0 | 0,37 | 2.3 | 73х173х145 | reduced! | |

| 6SL3210-1SB14-0AA0 | 0,75 | 3.9 | 73х173х145 | reduced! | |

SINAMICS S120 general industrial series / without EMC filter (3 phase 380-480 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| 6SL3210-1SE11-3UA0 | 0,37 | 1.3 | 73х173х145 | reduced! | |

| 6SL3210-1SE11-7UA0 | 0,55 | 1.7 | 73х173х145 | reduced! | |

| 6SL3210-1SE12-2UA0 | 0,75 | 2.2 | 73х173х145 | reduced! | |

| 6SL3210-1SE13-1UA0 | 1,1 | 3.1 | 73х173х145 | reduced! | |

| 6SL3210-1SE14-1UA0 | 1,5 | 4.1 | 73х173х145 | reduced! | |

| 6SL3210-1SE16-0UA0 | 2,2 | 5.9 | 153х270х165 | reduced! | |

| 6SL3210-1SE17-7UA0 | 3 | 7.7 | 153х270х165 | reduced! | |

| 6SL3210-1SE21-0UA0 | 4 | 10.2 | 153х270х165 | reduced! | |

| 6SL3210-1SE21-8UA0 | 7,5 | 18 | 188,4х333,4х185 | reduced! | |

| 6SL3210-1SE22-5UA0 | 11 | 25 | 188,4х333,4х185 | reduced! | |

| 6SL3210-1SE23-2UA0 | 15 | 32 | 188,4х333,4х185 | reduced! | |

| 6SL3210-1SE23-8UA0 | 18,5 | 38 | 275х418,3х203,5 | reduced! | |

| 6SL3210-1SE24-5UA0 | 22 | 45 | 275х418,3х203,5 | reduced! | |

| 6SL3210-1SE26-0UA0 | 30 | 60 | 275х418,3х203,5 | reduced! | |

| 6SL3210-1SE27-5UA0 | 37 | 75 | 275х418,3х203,5 | reduced! | |

| 6SL3210-1SE31-0UA0 | 45 | 90 | 275х418,3х203,5 | reduced! | |

| 6SL3210-1SE31-1UA0 | 55 | 110 | 350х634х315,5 | reduced! | |

| 6SL3210-1SE31-5UA0 | 75 | 145 | 350х634х315,5 | reduced! | |

| 6SL3210-1SE31-8UA0 | 90 | 178 | 350х634х315,5 | reduced! | |

SINAMICS S120 general industrial series / with EMC filter (3 phase 380-480 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| 6SL3210-1SE16-0AA0 | 2,2 | 5.9 | 153х270х165 | reduced! | |

| 6SL3210-1SE17-7AA0 | 3 | 7.7 | 153х270х165 | reduced! | |

| 6SL3210-1SE21-0AA0 | 4 | 10.2 | 153х270х165 | reduced! | |

| 6SL3210-1SE21-8AA0 | 7,5 | 18 | 188,4х333,4х185 | reduced! | |

| 6SL3210-1SE22-5AA0 | 11 | 25 | 188,4х333,4х185 | reduced! | |

| 6SL3210-1SE23-2AA0 | 15 | 32 | 188,4х333,4х185 | reduced! | |

| 6SL3210-1SE23-8AA0 | 18,5 | 38 | 275х511х203,5 | reduced! | |

| 6SL3210-1SE24-5AA0 | 22 | 45 | 275х511х203,5 | reduced! | |

| 6SL3210-1SE26-0AA0 | 30 | 60 | 275х511х203,5 | reduced! | |

| 6SL3210-1SE27-5AA0 | 37 | 75 | 275х633х203,5 | reduced! | |

| 6SL3210-1SE31-0AA0 | 45 | 80 | 275х633х203,5 | reduced! | |

| 6SL3210-1SE31-1AA0 | 55 | 110 | 350х934х315,5 | reduced! | |

| 6SL3210-1SE31-5AA0 | 75 | 145 | 275х633х203,5 | reduced! | |

| 6SL3210-1SE31-8AA0 | 90 | 178 | 275х633х203,5 | reduced! | |

Siemens frequency inverter SINAMICS S120 series - The best perspectives for a productive future.

High degree of flexibility for successful machine designs.

As member of the SINAMICS drive family, the modular S120 platform addresses demanding applications in plant construction and machine building. Single- and multi-axis drives sporting a high dynamic performance with integrated comprehensive functionality, along with a scalable number of axes, can address almost any drive application. The SINAMICS S120 facilitates the implementation of flexible and modular machine designs that can address specific customer requirements.

The answer to complex requirements.

Today, machines have to be manufactured even more costeffectively—and should offer end-users increasingly higher degrees of productivity. Our SINAMICS S120 drive system addresses both of these goals. Its sophisticated functionality and high dynamic performance facilitate new and innovative machine designs and significantly increase production yield. In addition, simple operation and maintenance increase the availability and reduce overall lifecycle costs. In other words—SINAMICS S120 increases the competitiveness of both manufacturers and end-users.

Modularity for machine building.

The SINAMICS S120 is flexibly-designed to support the modular demands of machine building. This includes:

- Single-axis and multi-axis drives

- Distributed multi-axis drives with the power unit mounted on the motor to minimize the cabinet size

- Integrated motion control functions in the drive system (SIMOTION D).

As modular machine designs can be created, you are always in a position to address the range of variants in demand — now and in the future.

Applications in machine building.

The SINAMICS S120 platform boosts the performance of your machines—no matter if it involves continuous material webs or clocked and highly-dynamic processes such as:

- Packaging machines

- Plastics machines

- Textile machines

- Printing machines

- Paper machines

- Hoisting gear

- Handling and assembly systems

- CNC machine tools

- Rolling mills

- Test stands.

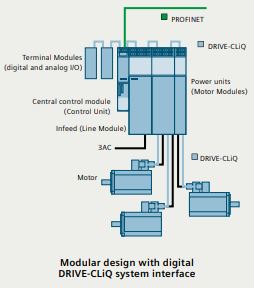

Siemens drive SINAMICS S120 series modular portfolio from the Control Unit to the cabling.

Flexibility and scalability as a result of the modular design.

Multi-axis devices set themselves apart as a result of modular design. The complete drive intelligence is embedded in the Control Units (CU). The CU handles all of the closed-loop control functions in the drive lineup and it executes all of the other drive functions—for example logically combining drive-related I/O, positioning functions, etc.—while having PROFIBUS DP or PROFINET as central interfaces to connect to higher-level automation systems. SIMOTION D or SINUMERIK can be used as special control units for motion control or CNC applications. SIMOTION D devices are modular control units that also have an integrated motion control system—in addition to the closed-loop drive control. SINUMERIK CNCs are modular control units to automate machine tools. Line modules supply the central DC link to which the motor modules (power units) are connected. Depending upon the selected line module type, energy can be fed back into the three-phase line supply, the DC link voltage can be controlled and line harmonics can be reduced. Energy is exchanged between motoring and generating motor modules via the central DC link. Only the summated or excess energy is drawn from or injected back into the line supply—or is dissipated in braking resistors. Drive-related inputs / outputs can be expanded using terminal modules Drive systems in the Booksize format facilitate an especially compact design. Double axis modules allow the width of Booksize devices to be reduced.

Intelligent products for more drive.

Control Unit modules.

Control Unit (CU) modules represent the central intelligence of an S120 drive system. In addition to the basic functions, such as operating system, communication and closed-loop control, they also include the user configuration. A distinction is made between the following versions:

- CU320-2 control unit. The control module for several drives.

- SIMOTION D4x5-2. Motion control for the coordinated operation of several drives.

- SINUMERIK NCU 7x0.3 PN. The CNC system for the mediumand upper-performance range.

I/O modules.

In addition to the I/O of the CU modules, I/O modules represent the connection of the drive system to the plant. The following are available:

- Binary inputs and outputs, also fail safe

- Relay outputs

- Analog inputs and outputs

- Fast inputs / outputs, e.g. for cam sequencers

- Modules to connect motor and machine encoders without the DRIVE-CLiQ interface

- Temperature evaluation (KTY84-130 or PTC)

DRIVE-CLiQ digital interface— low wiring costs.

The components of the S120 drive system communicate via the DRIVE-CLiQ system interface.

Essential features include:

- They connect Motor Modules, I/O modules etc. with the CU

- They connect motor encoders, where relevant, with electronic type plates for encoder and motor, as well as machine encoder

- Simple wiring using a plug-in system based on the RJ45 standard.

Product variance can be reduced and stock inventory costs minimized as a result of the standard cable and plug connector systems used. Additionally, commissioning time and costs are reduced as a result of the lower amount of work required.

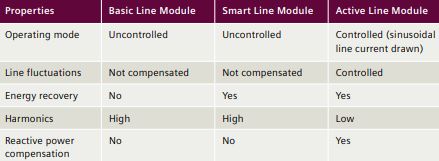

The Siemens SINAMICS S120 series optimal line infeed.

Basic Line Modules.

Our Basic Line Modules are used for applications where energy must only be taken from the line supply. If an excessive amount of energy is regenerated, then this must be dissipated in a braking resistor using a braking module (braking chopper). Highlights include:

- Space-savings

- Optimized cost

- For applications without, or only a low level of excessive braking energy

Smart Line Modules.

Use our Smart Line Modules if, in addition to drawing energy from the line supply, energy must also be fed back into the line supply. Using an additional braking module with braking resistor, drives can be braked in a specific way even when the power fails. Highlights include:

- Space-savings

- Energy recovery

- For applications with excess braking energy

Active Line.

Modules Self-commutated infeed /regenerative feedback units are suitable for motoring and regenerative operation. The Active Line Module can be used for reactive power compensation. Like a Smart Line Module, it’s also possible to use a braking chopper. Highlights include:

- Low line harmonics as a result of the almost sinusoidal line current characteristics

- Controlled DC link voltage, essentially decoupled from the line supply, suitable for high-speed applications— for example cross-cutters, even when connected to weak line supplies

- For applications with excess braking energy

- Power factor cosφ1 = 1, or can be adjusted.

Independent of the Line Module type, energy is always exchanged between the individual drives through the DC link.

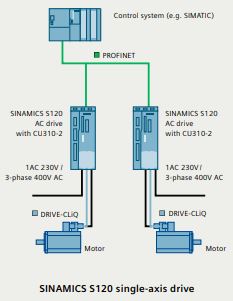

Siemens SINAMICS S120 series - Independent single-motor drive with Control Unit and Power Module.

Typical application areas.

Single-axis drives are suitable for every application—for example, travel drives, centrifuges, elevators and extruders, as well as mixers and kneaders. Single-axis SINAMICS S120 AC drives are also the ideal solution for multi-axis applications, where the drive axes are located remotely from each other. The same is true for modular machine concepts, which are being increasingly implemented in the packaging and woodworking industry. For single-axis drives, the line infeed and the power supply of the motor are combined into one device—the power module. For single-axis applications, closed-loop drive control is handled by a single axis control unit (e.g. CU310-2) mounted onto the power module; or for multi-axis applications, using a control unit (e.g. CU 320-2) coupled via DRIVE-CLiQ. In the latter case, instead of the control unit, a CU adapter is mounted onto the power module. Coupled decentrally via PROFIBUS DP or PROFINET to a higher-level control system, positioning tasks in automatic assembly machines and handling systems can be reliably tackled by SINAMICS S120 AC drives.

Central control intelligence interfacing to the control system—CU310-2 control unit.

AC drives are equipped with a CU310-2 control unit for coupling to a higher-level control. It offers functions from a basic speed controller up to extensive positioning functions. CU310-2 DP with PROFIBUS DP connection or CU310-2 PN with integrated PROFINET interface are available. Driverelated inputs / outputs in the CU can be simply and logically combined using BICO technology. As a result, the highest possible degree of decoupling between the drive and higherlevel control system can be achieved. For AC drives, when required, an additional encoder and drive-related I/O can be connected via DRIVE-CLiQ.

Motion Control integrated in the drive— SIMOTION D410 control unit.

The SIMOTION D410 control unit is the ideal solution if, beyond the closed-loop control intelligence, motion control is required for an axis and PLC functionality in a compact format. SIMOTION D410 can be used for single-axis applications, such as winders, cross cutters and feed equipment, or also in synchronous groups as is the case for modular machine designs. The machine module automated with SIMOTION D410 receives the master value from a higher-level control system and synchronizes its axis to this leading value. D410 DP with PROFIBUS DP connection or D410 PN with integrated PROFINET interface can be selected. Up to four fast cam outputs or three probe inputs can be implemented using the onboard inputs / outputs.

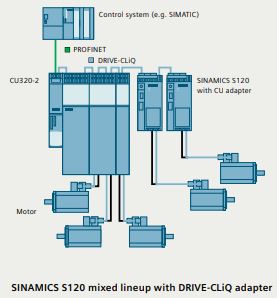

CUA31 / 32 control unit adapter for multi-axis applications with SINAMICS S120 AC drive.

The drive is connected to a multi-axis control unit, e.g. CU320-2, using the CU adapter CUA31 via the DRIVE-CLiQ interface. This control unit then handles drive functionality for the AC drive. In this configuration, SINAMICS S120 AC drives can also be used in mixed operation with SINAMICS S120 multi-axis devices. This facilitates maximum flexibility when using SINAMICS S120 devices. In comparison to the CUA31, the CUA32 also has an integrated HTL / TTL encoder interface to connect an external encoder.

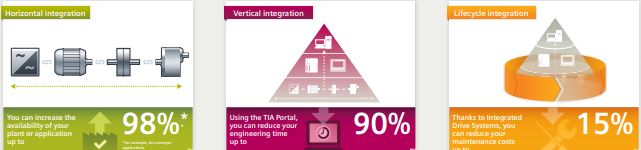

Siemens frequency inverter SINAMICS S120 series - for higher efficiency, reliability and productivity.

Triple integration creates a true value-add.

Horizontal integration.

The integrated drive portfolio—all drives, motors, couplings and gearboxes are available from a single source. Perfectly integrated, perfect inter-operability—for every power and performance class as a standard solution or as a completely customized solution.

Vertical integration.

Integrated in the automation technology — from the field through the controller level, up to the manufacturing execution system (MES) thanks to Totally Integrated Automation — for each and every application.

Lifecycle integration.

Integrated software and services over the complete lifecycle—extensive software tools and expert service for the complete lifecycle, from planning, to the engineering of the application, up to service—for higher performance and maximum investment security.

The optimal solution for each and every task.

The drive solution that offers you everything.

The wide range of functionality and flexibility make SINAMICS S120 the universal drive solution for machine building. A broad range of motors and control systems optimally tailored to address the various applications permits fully integrated solutions—simple to design, commission and operate. The motors are connected to the power units through pre-fabricated Motion Connect power and data cables. Electronic motor nameplates guarantee reliable auto-parameterization of the drive lineup. In operation, the encoder values are transferred to the drive line-up in real time via the DRIVE-CLiQ interface. The drive is connected to the automation system via the various connectivity to fieldbuses and industrial ethernet networks.

Synchronous and induction motors can be operated with SINAMICS S120.

In addition to its range of SIMOTICS low-voltage motors, Siemens also has a wide range of different motor types specifically designed for motion control applications.

- SIMOTICS low-voltage motors: standard and reluctance motors, plus explosion-protected versions for almost every industrial application

- SIMOGEAR gear motors

- SIMOTICS-S servomotors: optionally equipped with various gearbox types, for high-speed positioning tasks, clocked axes and feed drives

- SIMOTICS-M main motors: for high-speed, high-precision rotary axes, e.g. for winding and synchronous operation applications—as well as main spindles in machine tools

- SIMOTICS-L linear motors: for positioning and feed axes demanding the highest dynamic performance.

- SIMOTICS-T torque motors: directly mounted to the machine component demanding the highest dynamic performance.