|

BFI P2 frequency inverter combine premium control of both standard induction motors and permanent magnet motors with high performance, reliability and ease of use. Extensive I/O and communications interface capabilities ensure, the drive can be integrated quickly and efficiently into a wide variety of control systems and the simple parameter structure with carefully selected factory settings provide fast and easy commissioning. The inverters offer open loop vector control of standard induction motors providing up to 200% torque from zero speed as well as closed loop encoder feedback capability. For the latest generation of high efficiency PM motors the inverters offer open and closed loop control. The choice of control method and motor type provides premium control and optimum energy efficiency for the actual application.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads  Request additional information and get a price quote Request additional information and get a price quote |

Model range

BFI P2 industrial series (1 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| BFI-P2-22-0043-1F42-SN | 0.75 | 4.3 | 112x221x185 | reduced! | |

| BFI-P2-22-0043-1F4YTN | 0.75 | 4.3 | 188x257x238 | reduced! | |

| BFI-P2-22-0070-1F42-SN | 1.5 | 7 | 112x221x185 | reduced! | |

| BFI-P2-22-0070-1F4Y-TN | 1.5 | 7 | 188x257x238 | reduced! | |

| BFI-P2-22-0105-1F42-SN | 2.2 | 10.5 | 112x221x185 | reduced! | |

| BFI-P2-22-0105-1F4Y-TN | 2.2 | 10.5 | 188x257x238 | reduced! | |

BFI P2 industrial series (3 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| BFI-P2-22-0043-3F42-SN | 0.75 | 4.3 | 112x221x185 | reduced! | |

| BFI-P2-22-0043-3F4Y-TN | 0.75 | 4.3 | 188x257x238 | reduced! | |

| BFI-P2-22-0070-3F42-SN | 1.5 | 7 | 112x221x185 | reduced! | |

| BFI-P2-22-0070-3F4Y-TN | 1.5 | 7 | 188x257x238 | reduced! | |

| BFI-P2-22-0105-3F42-SN | 2.2 | 10.5 | 112x221x185 | reduced! | |

| BFI-P2-22-0105-3F4Y-TN | 2.2 | 10.5 | 188x257x238 | reduced! | |

| BFI-P2-32-0180-3F42-SN | 4 | 18 | 131x261x205 | reduced! | |

| BFI-P2-32-0180-3F4Y-TN | 4 | 18 | 211x310x256 | reduced! | |

| BFI-P2-32-0240-3F42-SN | 5.5 | 24 | 131x261x205 | reduced! | |

| BFI-P2-42-0240-3F4N-TN | 5.5 | 24 | 171x440x240 | reduced! | |

| BFI-P2-42-0300-3F4N-TN | 7.5 | 30 | 171x440x240 | reduced! | |

| BFI-P2-42-0460-3F4N-TN | 11 | 46 | 171x440x240 | reduced! | |

| BFI-P2-52-0610-3F4N-TN | 15 | 61 | 235x540x270 | reduced! | |

| BFI-P2-52-0720-3F4N-TN | 18.5 | 72 | 235x540x270 | reduced! | |

| BFI-P2-62-0900-3F1N-TN | 22 | 90 | 330x865x330 | reduced! | |

| BFI-P2-62-1100-3F1N-TN | 30 | 110 | 330x865x330 | reduced! | |

| BFI-P2-62-1500-3F1N-TN | 37 | 150 | 330x865x330 | reduced! | |

| BFI-P2-62-1800-3F1N-TN | 45 | 180 | 330x865x330 | reduced! | |

| BFI-P2-72-2020-3F1N-TN | 55 | 202 | 330x1280x360 | reduced! | |

| BFI-P2-72-2480-3F1N-TN | 75 | 248 | 330x1280x360 | reduced! | |

BFI P2 industrial series (3 phase 380-480 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| BFI-P2-24-0022-3F42-SN | 0.75 | 2.2 | 112x221x185 | reduced! | |

| BFI-P2-24-0022-3F4Y-TN | 0.75 | 2.2 | 188x257x238 | reduced! | |

| BFI-P2-24-0041-3F42-SN | 1.5 | 4.1 | 112x221x185 | reduced! | |

| BFI-P2-24-0041-3F4Y-TN | 1.5 | 4.1 | 188x257x238 | reduced! | |

| BFI-P2-24-0058-3F42-SN | 2.2 | 5.8 | 112x221x185 | reduced! | |

| BFI-P2-24-0058-3F4Y-TN | 2.2 | 5.8 | 188x257x238 | reduced! | |

| BFI-P2-24-0095-3F42-SN | 4 | 9.5 | 112x221x185 | reduced! | |

| BFI-P2-24-0095-3F4Y-TN | 4 | 9.5 | 188x257x238 | reduced! | |

| BFI-P2-34-0140-3F42-SN | 5.5 | 14 | 131x261x205 | reduced! | |

| BFI-P2-34-0140-3F4Y-TN | 5.5 | 14 | 211x310x256 | reduced! | |

| BFI-P2-34-0180-3F42-SN | 7.5 | 18 | 131x261x205 | reduced! | |

| BFI-P2-34-0180-3F4Y-TN | 7.5 | 18 | 211x310x256 | reduced! | |

| BFI-P2-34-0240-3F42-SN | 11 | 24 | 131x261x205 | reduced! | |

| BFI-P2-44-0240-3F4N-TN | 11 | 24 | 171x440x240 | reduced! | |

| BFI-P2-44-0300-3F4N-TN | 15 | 30 | 171x440x240 | reduced! | |

| BFI-P2-44-0390-3F4N-TN | 18 | 39 | 171x440x240 | reduced! | |

| BFI-P2-44-0460-3F4N-TN | 22 | 46 | 171x440x240 | reduced! | |

| BFI-P2-54-0610-3F4N-TN | 30 | 61 | 235x540x270 | reduced! | |

| BFI-P2-54-0720-3F4N-TN | 37 | 72 | 235x540x270 | reduced! | |

| BFI-P2-64-0900-3F4N-TN | 45 | 90 | 330x865x330 | reduced! | |

| BFI-P2-64-1100-3F4N-TN | 55 | 110 | 330x865x330 | reduced! | |

| BFI-P2-64-1500-3F4N-TN | 75 | 150 | 330x865x330 | reduced! | |

| BFI-P2-64-1800-3F4N-TN | 90 | 180 | 330x865x330 | reduced! | |

| BFI-P2-74-2020-3F4N-TN | 110 | 202 | 330x1280x360 | reduced! | |

| BFI-P2-74-2400-3F1N-TN | 132 | 240 | 330x1280x360 | reduced! | |

| BFI-P2-74-3020-3F4N-TN | 160 | 302 | 330x1280x360 | reduced! | |

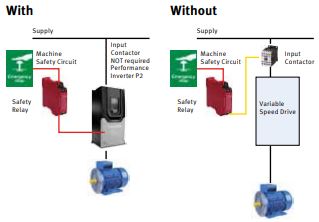

Beijer Electronics performance inverter BFI P2 series features a safe torque off function to allow simple integration into machine critical safety circuits.

- Simple machine design reduces component costs, saves panel space and minimizes installation time

- Faster shut down and reset procedures reduce system maintenance time

- Better safety standard compared to mechanical solution

- Better motor connection

- Single cable with no interruption

World leading motor control.

The Performance Inverter P2 offers the perfect combination of high performance together with ease of use to allow even the most demanding applications to be tackled easily.

- Designed for fast installation and commissioning, Performance Inverter P2 provides the most cost effective solution for industry.

- All Performance Inverter P2 units provide 150% overload for 60 seconds as standard, 200% overload for 2 seconds, ensuring each drive is suitable for heavy duty applications, whilst the IP55/IP66 enclosed versions ensure the drive is tough enough to survive in industrial environments.

- Extensive I/O and communications interface capabilities ensure the drive can be integrated quickly and efficiently into a wide variety of control systems with the minimum commissioning time, ensuring rapid start-up. The simple parameter structure and carefully selected factory parameter settings ensure that commissioning time is kept to a minimum.

Advanced motor control with Beijer Electronics drive BFI P2 series.

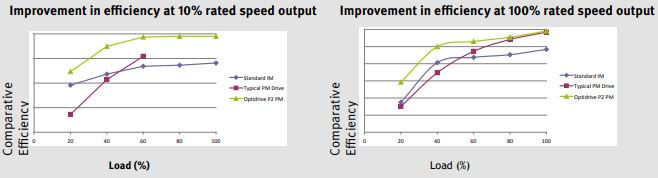

Drive system efficiency.

With today’s ever increasing energy costs, efficiency is a key factor in relation to drive system component selection. In many cases, an efficiency figure can be arrived at by simply multiplying the efficiencies of the various components together to find a combined efficiency figure, however this may not tell the whole story. The efficiency of components such as drives, motors and gearboxes can vary considerably with speed and load, hence simply combining the ‘headline’ efficiency figures can often be very misleading. In reality, the efficiency curves for the whole system should be overlaid, to provide a true efficiency figure for the system across the desired speed and load range. Modern AC inverters will typically have an electrical efficiency of around 98%, which represents the difference between the electrical output power compared to electrical input power only. A further factor that is often overlooked is the efficiency of the motor control strategy employed by the drive. This can have a significant effect on the overall system efficiency and is often not considered when energy saving calculations are made.

Future-proof energy efficiency.

Performance Inverter P2 has been designed and developed to work with both standard induction motors, which typically meet the IE2 efficiency standards currently in place in Europe, and the latest generation of high efficiency PM motors designed to meet the future IE4 requirements. This means that an efficient drive can now be purchased, allowing for a future update of the motor without requiring a change to the installed drive. Performance Inverter P2 works with all PM motors, controlling them with optimum efficiency for the most efficient PM motor control available.

The graphs below clearly demonstrate these factors:

- The overall efficiency of the system varies with speed and load and is not a constant.

- Motor control efficiency significantly affects overall system efficiency.

- The graphs are generated by measuring the electrical power drawn from the mains supply compared to the torque generated at the output shaft. These are based on a system requirement of 2.2kW motor power generated at the output shaft. These are based on a system requirement of 2.2kW motor power.