|

The new Agile series of inverter drives from Bonfiglioli sets new standards in technology for a broad range of users. Agile VFD are particularly suited to the food and beverage, textile, wood, packaging and ceramic industries, where they can be used with a variety of medium complex automation process. Agile inverter drives AGL402 and AGL202 implement a sensorless vector control algorithm that offers excellent performance in speed and torque control. A wide range of built-in functions deliver significant benefits to users seeking safety, energy savings, diagnostics, reliability and local intelligence.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

Agile series (1/3 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| AGL202 02 1 FA | 0.12 / 0.25 | 1 / 1.5 | 60x200x170 | 302,00 € | |

| AGL202 03 1 FA | 0.18 / 0.37 | 1.3 / 2 | 60x200x170 | 313,00 € | |

| AGL202 05 1 FA | 0.25 / 0.55 | 1.5 / 3 | 60x200x170 | 325,00 € | |

| AGL202 07 1 FA | 0.37 / 0.75 | 2 / 3.5 | 60x200x170 | 337,00 € | |

| AGL202 09 1 FA | 0.55 / 1.1 | 3 / 5 | 60x200x170 | 342,00 € | |

| AGL202 11 1 FA | 0.75 / 1.5 | 3.5 / 6 | 60x200x170 | 354,00 € | |

| AGL202 13 1 FA | 1.1 / 2.2 | 5 / 9 | 60x200x170 | 365,00 € | |

| AGL202 15 2 FA | 1.5 / 3 | 6 / 12 | 80x200x196 | 410,00 € | |

| AGL202 18 2 FA | 2.2 / 4 | 9 / 15 | 80x200x196 | 467,00 € | |

| AGL202 19 3 FA | 3 / 5.5 | 12 / 21 | 125x200x205 | 558,00 € | |

| AGL202 21 3 FA | 3 / 7.5 | 12 / 26 | 125x200x205 | 616,00 € | |

Agile series (3 phase 380-480 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| AGL402 02 1 FA | 0.25 | 0.8 | 60x200x170 | 302,00 € | |

| AGL402 03 1 FA | 0.37 | 1.2 | 60x200x170 | 313,00 € | |

| AGL402 05 1 FA | 0.55 | 1.5 | 60x200x170 | 325,00 € | |

| AGL402 07 1 FA | 0.75 | 2.1 | 60x200x170 | 337,00 € | |

| AGL402 09 1 FA | 1.1 | 3 | 60x200x170 | 371,00 € | |

| AGL402 11 1 FA | 1.5 | 4 | 60x200x170 | 399,00 € | |

| AGL402 13 1 FA | 2.2 | 5.5 | 60x200x170 | 455,00 € | |

| AGL402 15 2 FA | 3 | 7.5 | 80x200x196 | 525,00 € | |

| AGL402 18 2 FA | 4 | 9.5 | 80x200x196 | 581,00 € | |

| AGL402 19 2 FA | 5.5 | 13 | 80x200x196 | 770,00 € | |

| AGL402 21 2 FA | 7.5 | 17 | 80x200x196 | 889,00 € | |

| AGL402 19 3 FA | 5.5 | 13 | 125x200x205 | 832,00 € | |

| AGL402 21 3 FA | 7.5 | 17 | 125x200x205 | 889,00 € | |

| AGL402 22 3 FA | 9.2 | 20 | 125x200x205 | 1 003,00 € | |

| AGL402 23 3 FA | 11 | 23 | 125x200x205 | 1 026,00 € | |

Agile series (1/3 phase 200-240 V), Spindel-Software

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| AGLS202 02 1 FA | 0.12 / 0.25 | 1 / 1.5 | 60x200x170 | 332,00 € | |

| AGLS202 03 1 FA | 0.18 / 0.37 | 1.3 / 2 | 60x200x170 | 345,00 € | |

| AGLS202 05 1 FA | 0.25 / 0.55 | 1.5 / 3 | 60x200x170 | 357,00 € | |

| AGLS202 07 1 FA | 0.37 / 0.75 | 2 / 3.5 | 60x200x170 | 370,00 € | |

| AGLS202 09 1 FA | 0.55 / 1.1 | 3 / 5 | 60x200x170 | 376,00 € | |

| AGLS202 11 1 FA | 0.75 / 1.5 | 3.5 / 6 | 60x200x170 | 389,00 € | |

| AGLS202 13 1 FA | 1.1 / 2.2 | 5 / 9 | 60x200x170 | 401,00 € | |

| AGLS202 15 2 FA | 1.5 / 3 | 6 / 12 | 80x200x196 | 451,00 € | |

| AGLS202 18 2 FA | 2.2 / 4 | 9 / 15 | 80x200x196 | 514,00 € | |

| AGLS202 19 3 FA | 3 / 5.5 | 12 / 21 | 125x200x205 | 615,00 € | |

| AGLS202 21 3 FA | 3 / 7.5 | 12 / 26 | 125x200x205 | 677,00 € | |

Agile series (3 phase 380-480 V), Spindel-Software

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| AGLS402 02 1 FA | 0.25 | 0.8 | 60x200x170 | 332,00 € | |

| AGLS402 03 1 FA | 0.37 | 1.2 | 60x200x170 | 345,00 € | |

| AGLS402 05 1 FA | 0.55 | 1.5 | 60x200x170 | 357,00 € | |

| AGLS402 07 1 FA | 0.75 | 2.1 | 60x200x170 | 370,00 € | |

| AGLS402 09 1 FA | 1.1 | 3 | 60x200x170 | 408,00 € | |

| AGLS402 11 1 FA | 1.5 | 4 | 60x200x170 | 439,00 € | |

| AGLS402 13 1 FA | 2.2 | 5.5 | 60x200x170 | 501,00 € | |

| AGLS402 15 2 FA | 3 | 7.5 | 80x200x196 | 577,00 € | |

| AGLS402 18 2 FA | 4 | 9.5 | 80x200x196 | 639,00 € | |

| AGLS402 19 2 FA | 5.5 | 13 | 80x200x196 | 851,00 € | |

| AGLS402 21 2 FA | 7.5 | 17 | 80x200x196 | 919,00 € | |

| AGLS402 19 3 FA | 5.5 | 13 | 125x200x205 | 915,00 € | |

| AGLS402 21 3 FA | 7.5 | 17 | 125x200x205 | 977,00 € | |

| AGLS402 22 3 FA | 9.2 | 20 | 125x200x205 | 1 103,00 € | |

| AGLS402 23 3 FA | 11 | 23 | 125x200x205 | 1 129,00 € | |

Advanced technologies for all industrial fields.

The new Agile Series of inverter drives from Bonfiglioli sets new standards in technology for a broad range of users. Agile drives are particularly suited to the food & beverage, textile, wood, packaging and ceramic industries, where they can be used with a variety of medium complex automation processes. Agile inverter drives implement a sensorless vector control algorithm that offers excellent performance in speed and torque control. A wide range of built-in functions deliver significant benefits to users seeking safety, energy savings, diagnostics, reliability and local intelligence. The innovative user-friendliness of these drives is evident from the word ‘go’. Even inexperienced users will find installation and start-up quick and easy. Agile inverter drives are designed for reliability at component, machine and process levels. Software functions have been specially developed to inform users of the ideal time to perform maintenance in order to ensure continuous service from the plant. Transparent control is ensured by Agile drives’ ability to accurately diagnose themselves and surrounding components in order to avoid faults and failures in the system. Reliable and generous, Agile drives also boast special functions designed to reduce programming costs. These functions facilitate the selection and setting of software parameters and provide a speedy and intuitive man-machine interface. The advanced energy saving functions, adaptability and robustness of Agile inverter drives reduces impact on the environment, too. Integrated PLC functions allow Agile drives to achieve a practical level of autonomy. The CPU not only controls the motor, but also provides the user with a number of programmable logic functions that can be used to complement or replace PLC’s and process controllers.

Overview of Bonfiglioli frequency inverter Agile series.

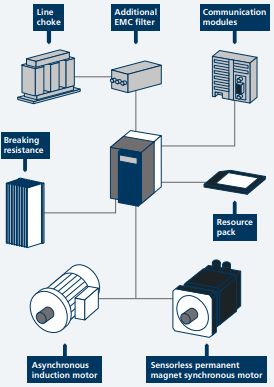

Agile inverter drives are designed to control asynchronous induction motors and permanent magnet synchronous servomotors. With their sleek, compact cases, Agile drives have been specially developed for maximum functional integration. With a wide range of hi-tech functions already built in, Agile drives are complete and fully functional drives despite their small size. Thanks to intelligent design, the generous and advanced standard functions can be expanded by accessories and optional modules to extend versatility even further.

Bonfiglioli drive Agile series - innovation at the service of people.

Agile inverter drives help bridge the gap between user and process by providing software and hardware functions that simplify the management of complete systems.

Agile inverter process drives provide accurate sensorless vector control of asynchronous induction motors and permanent magnet synchronous motors, and also help manage the complete automation system by contributing to energy saving, safety, maintenance and logic control. Agile drives are Bonfiglioli’s solution to the needs of the standard drive market, and boast a special “all-in-one” formula that delivers exceptional versatility.

Sensorless control of permanent magnet synchronous motors.

In brushless motor control, the exact angular position of the rotor must be known at all times for the drive to commutate the inverter phases. The conventional method for tracking rotor position is to incorporate an encoder or resolver inside the servomotor to provide the drive with the necessary electrical signals. This, however, requires extra cabling, data interfaces and controls. Thanks to innovative technology, Agile drives can control brushless servomotors without the need for sensors, eliminating the cost of superfluous components, wiring, interfaces and controls. Agile drives use efficient algorithms to calculate the instantaneous angular position of the motor shaft from measurements of the current absorbed by the motor. This gives significant savings in costs, eliminates the criticalities inherent in sensors, simplifies the control system and reduces energy consumption by permitting a more efficient motor architecture to be used. By combining analytic techniques to reconstruct the electrical status of the motor and functional analyses of its magnetic circuit, Agile drives provide effective vector control of torque.

Bonfiglioli vfd Agile series is energy saving.

Energy saving is a common objective in all areas of manufacturing. No company is exempt from the need to save money and help the environment at the same time. If energy saving is your aim, Agile is the drive to help you achieve it. AgileE drives incorporate numerous functions for reducing the electrical energy needed to power motors and can make a major contribution to energy saving in any plant. Bonfiglioli knows exactly what factors determine a drive’s energy efficiency and how to achieve major energy savings. Now all this know-how has been concentrated into a single product.

Sensorless control of permanent magnet synchronous motors.

Modern brushless motors are extremely efficient thanks to a design that favours excellent electromechanical energy conversion and minimises heat loss through the rotor. Agile drives are designed to bring the benefits of brushless motor technology within the reach of all users. Agile drives do not need encoders or resolvers on board the motors to control them. They can therefore save money by eliminating superfluous components, without any loss of dynamic motor performance.

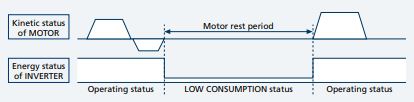

Standby mode.

Motors are often used in applications involving intermittent functioning cycles characterised by alternating run and rest phases. Under conditions like these, the drive itself has to remain powered on in order to be ready to start the motor as soon as the application demands. To avoid unnecessary energy consumption during motor rest periods without actually disconnecting power to the inverter, Agile drives use a special auto-standby function, which leaves the inverter in a “sleep” condition with only its control circuits active, a condition in which energy consumption is minimal. A programmable delay can be adjusted by users in order to extend the standby mode even to keypad display. As soon as a start command is received, the inverter “wakes up” immediately to power the motor.

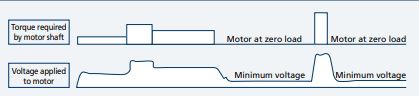

Power managing.

Motor efficiency is significantly conditioned by the quality of the power supply. Agile drives use control to reduce motor voltage to suit applied loads without compromising performance. This reduces motor losses, consumption and maintenance requirements and helps extend motor life. For example, if the motor is run up to rated speed at zero load, there is no need to apply full rated voltage. The minimum voltage compatible with the needs of motor magnetisation is all that is needed.

Minimum earth leakage.

Agile drives are equipped with a built-in, low leakage current EMC filter that conforms to all applicable standards. By significantly reducing earth leakage, this filter also maximises energy savings under all operating conditions.

Bonfiglioli vfd Agile series has a built in PLC.

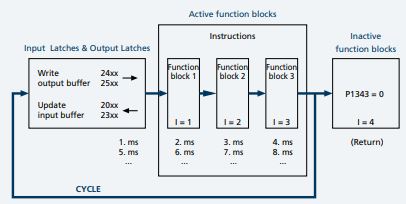

The OS scans input and output buffers, samples input signals and executes output signals before it indexes the sequence of active modules.

As in any control panel PLC, cycle management is entrusted to the operating system and is independent of all other processes managed by the CPU. The program is therefore deterministic and scan time proportional to the number of active function blocks. In any automation process, the cycle period can be calculated by summing the 1-ms delays introduced by each function block. Agile PLC functions can be programmed using VPlus software, which graphically displays the program to which the drive’s memory corresponds in real time. VPlus software also provides a page that can be used to load graphic function blocks and link them together to create complex logic networks for use by the drive. The Agile PLC supports and processes all the variables used by the drive software, including I/O variables, strings exchanged over the field bus and numeric motor control values. The PLC is therefore perfectly able to exchange signals with external devices like sensors, actuators, inverters, PLCs, PC’s, etc.) as well as with the drive itself.

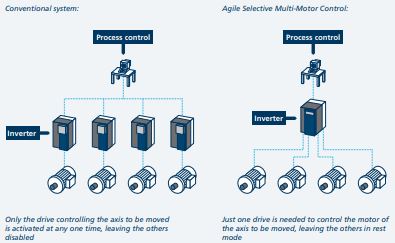

Bonfiglioli frequency inverter Agile series selective Multi-Motor Control (SMMC).

Industrial applications often require a number of axes to be controlled separately and driven one at a time in a predefined sequence in which no two motors operate simultaneously. In conventional systems of this type, each individual axis has to be controlled by its own drive, configured to power its motor for a set time and then to remain inactive while the control sequence passes on to the next axes. The process controller must therefore send each drive its own set of commands and must also transmit the necessary reference signals over a corresponding number of analog ports or network addresses. This requires a high level of redundancy in system components, cabling and control software and results in significant energy consumption. Agile drives are specially designed to provide efficient control of complex systems comprising multiple but non-simultaneous motors. AgilE drives can handle four separate motors even with different electrical characteristics, reserving a dedicated area of memory to the control of each. The architecture of Agile drives lets you store simultaneous configurations for all four motors and control them independently at separate times according to independent criteria and strategies, but using the same power hardware.

By using two digital inputs in binary combination mode, users can activate the drive’s parameter configuration corresponding to just one of the four motors, thus excluding the other three. The currently active control algorithm (V/Hz, sensorless vector control, sensorless brushless motor control) controls the selected motor and drives it according to the parameter settings in the corresponding dataset.