|

The VLT® HVAC Drive has a vast number of functions developed to meet the diverse needs of the HVAC business. Easy to use, all models follow the same basic design and operating principle. Once you know one, you know them all. It is the perfect match for pumps, fans and compressors in modern buildings that are fitted with increasingly sophisticated solutions.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

VLT HVAC Drive FC 102 series, 380-480 V (3 phase), IP20, RFI Class A1/B (C1), Graphical Local Control Panel (LCP-102)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-102P1K1T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 90x268x205 | 628,00 € | |

| FC-102P1K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 90x268x205 | 719,00 € | |

| FC-102P2K2T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 90x268x205 | 867,00 € | |

| FC-102P3K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 90x268x205 | 966,00 € | |

| FC-102P4K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 90x268x205 | 1 031,00 € | |

| FC-102P5K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 130x268x205 | 1 192,00 € | |

| FC-102P7K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 130x268x205 | 1 340,00 € | |

| FC-102P11KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 165x399x249 | 1 726,00 € | |

| FC-102P15KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 165x399x249 | 1 952,00 € | |

| FC-102P18KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 165x399x249 | 2 423,00 € | |

| FC-102P22KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 230x520x242 | 2 825,00 € | |

| FC-102P30KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 230x520x242 | 3 281,00 € | |

| FC-102P37KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 230x520x242 | 3 953,00 € | |

| FC-102P45KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 308x550x333 | 4 824,00 € | |

| FC-102P55KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 55 | 106 | 1-3600 | 308x550x333 | 5 836,00 € | |

| FC-102P75KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 370x660x333 | 6 728,00 € | |

| FC-102P90KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 370x660x333 | 7 872,00 € | |

VLT HVAC Drive FC 102 series, 380-480 V (3 phase), IP20, RFI Class A1/B (C1), Graphical Local Control Panel (LCP-102), Safe Stop

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-102P1K1T4E20H1TGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 90x268x205 | 652,00 € | |

| FC-102P1K5T4E20H1TGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 90x268x205 | 747,00 € | |

| FC-102P2K2T4E20H1TGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 90x268x205 | 900,00 € | |

| FC-102P3K0T4E20H1TGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 90x268x205 | 1 005,00 € | |

| FC-102P4K0T4E20H1TGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 90x268x205 | 1 072,00 € | |

| FC-102P5K5T4E20H1TGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 130x268x205 | 1 240,00 € | |

| FC-102P7K5T4E20H1TGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 130x268x205 | 1 393,00 € | |

| FC-102P11KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 165x399x249 | 1 789,00 € | |

| FC-102P15KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 165x399x249 | 2 021,00 € | |

| FC-102P18KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 165x399x249 | 2 515,00 € | |

| FC-102P22KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 230x520x242 | 2 935,00 € | |

| FC-102P30KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 230x520x242 | 3 409,00 € | |

| FC-102P37KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 230x520x242 | 4 110,00 € | |

| FC-102P45KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 308x550x333 | 5 016,00 € | |

| FC-102P55KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 55 | 106 | 1-3600 | 308x550x333 | 6 069,00 € | |

| FC-102P75KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 370x660x333 | 6 992,00 € | |

| FC-102P90KT4E20H1TGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 370x660x333 | 8 186,00 € | |

VLT HVAC Drive FC 102 series, 380-480 V (3 phase), IP20, RFI Class A2 (C3), Graphical Local Control Panel (LCP-102)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-102P1K1T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 90x268x205 | 565,00 € | |

| FC-102P1K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 90x268x205 | 648,00 € | |

| FC-102P2K2T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 90x268x205 | 778,00 € | |

| FC-102P3K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 90x268x205 | 866,00 € | |

| FC-102P4K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 90x268x205 | 922,00 € | |

| FC-102P5K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 130x268x205 | 1 062,00 € | |

| FC-102P7K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 130x268x205 | 1 189,00 € | |

| FC-102P11KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 165x399x249 | 1 518,00 € | |

| FC-102P15KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 165x399x249 | 1 733,00 € | |

| FC-102P18KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 165x399x249 | 2 178,00 € | |

| FC-102P22KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 230x520x242 | 2 549,00 € | |

| FC-102P30KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 230x520x242 | 2 962,00 € | |

| FC-102P37KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 230x520x242 | 3 625,00 € | |

| FC-102P45KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 308x550x333 | 4 433,00 € | |

| FC-102P55KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 55 | 106 | 1-3600 | 308x550x333 | 5 309,00 € | |

| FC-102P75KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 370x660x333 | 6 029,00 € | |

| FC-102P90KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 370x660x333 | 7 092,00 € | |

VLT HVAC Drive FC 102 series, 380-480 V (3 phase), IP20, RFI Class A2 (C3), Graphical Local Control Panel (LCP-102), Safe Stop

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| FC-102P1K1T4E20H2TGXXXXSXXXXAXBXCXXXXDX | 1.1 | 3 | 1-3600 | 90x268x205 | 589,00 € | |

| FC-102P1K5T4E20H2TGXXXXSXXXXAXBXCXXXXDX | 1.5 | 4.1 | 1-3600 | 90x268x205 | 675,00 € | |

| FC-102P2K2T4E20H2TGXXXXSXXXXAXBXCXXXXDX | 2.2 | 5.6 | 1-3600 | 90x268x205 | 811,00 € | |

| FC-102P3K0T4E20H2TGXXXXSXXXXAXBXCXXXXDX | 3 | 7.2 | 1-3600 | 90x268x205 | 905,00 € | |

| FC-102P4K0T4E20H2TGXXXXSXXXXAXBXCXXXXDX | 4 | 10 | 1-3600 | 90x268x205 | 963,00 € | |

| FC-102P5K5T4E20H2TGXXXXSXXXXAXBXCXXXXDX | 5.5 | 13 | 1-3600 | 130x268x205 | 1 110,00 € | |

| FC-102P7K5T4E20H2TGXXXXSXXXXAXBXCXXXXDX | 7.5 | 16 | 1-3600 | 130x268x205 | 1 242,00 € | |

| FC-102P11KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 11 | 24 | 1-3600 | 165x399x249 | 1 581,00 € | |

| FC-102P15KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 15 | 32 | 1-3600 | 165x399x249 | 1 805,00 € | |

| FC-102P18KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 18.5 | 37.5 | 1-3600 | 165x399x249 | 2 271,00 € | |

| FC-102P22KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 22 | 44 | 1-3600 | 230x520x242 | 2 658,00 € | |

| FC-102P30KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 30 | 61 | 1-3600 | 230x520x242 | 3 090,00 € | |

| FC-102P37KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 37 | 73 | 1-3600 | 230x520x242 | 3 782,00 € | |

| FC-102P45KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 45 | 90 | 1-3600 | 308x550x333 | 4 626,00 € | |

| FC-102P55KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 55 | 106 | 1-3600 | 308x550x333 | 5 542,00 € | |

| FC-102P75KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 75 | 147 | 1-3600 | 370x660x333 | 6 293,00 € | |

| FC-102P90KT4E20H2TGXXXXSXXXXAXBXCXXXXDX | 90 | 177 | 1-3600 | 370x660x333 | 7 405,00 € | |

3) Reduce costs with Danfoss VLT HVAC FC102 series safety compact drives

4) Freedom to design efficient systems

5) Danfoss VLT HVAC frequency inverter FC 102 platform highlights

6) Size and protection class- the perfect fit for Danfoss VLT HVAC drive FC 102 series

7) Danfoss VLT HVAC drive FC 102 are equipped with DC chokes that reduce mains interference to a THDi of 40%

8) Optimize performance and grid protection

9) Expand grid protection with filter solutions

10) Danfoss VLT HVAC inverter FC 102 uses motor cables up to 300m

11) Increased Danfoss VLT HVAC vfd FC 102 series safety

12) Nine fieldbuses supported

13) Energy documentation of Danfoss VLT HVAC drive FC 102 series

14) Danfoss VLT HVAC inverter FC 102 series has dedicated pump features

15)Product code list with corresponding models for Danfoss frequency inverters VLT HVAC Drive FC 102 series

Danfoss VLT HVAC drive FC 102 is flexible, modular and adaptable- built to last

The VLT® HVAC Drive is built on a flexible, modular design concept to provide an extraordinarily versatile motor control solution. Equipped with a wide range of HVAC features owners can achieve optimal fan and pump control, higher quality output and reduce costs related to spare parts and service, and much more.

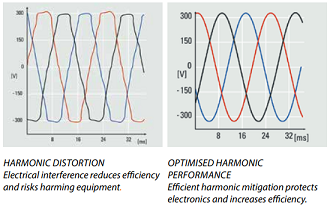

Built-in EMC filters

VLT® HVAC Drive units are equipped with integrated DC link chokes and EMC filters as standard features. This enables them to reduce grid pollution and eliminate the cost and effort of fitting external EMC components and related wiring.

Reduce costs with Danfoss VLT HVAC FC 102 series safety compact drives

A compact design and efficient heat management enable the drives to take up less space in control rooms and panels in all kinds of environments. Especially impressive is the 315 kW, 400 V version, which is among the smallest in its power class on the market today, and is available in an IP54 enclosure.

Compact dimensions are also an advantage in applications where drive space is restricted. This makes it possible for designers to develop smaller applications without being forced to compromise on protection and grid quality. For example, the D frame versions of the VLT® HVAC Drive FC102 from 110-400 kW are 25-68% smaller than equivalent drives.

The IP20 version is optimized for cabinet mounting and features covered power terminals to prevent accidentalcontact. The unit can also be ordered with optional fuses or circuit breakers in the same package size. Control and power cables are fed in separately at the bottom.

The frequency converters combine a flexible system architecture, which allows them to be adapted to specific applications, with a uniform user interface across all power classes. This allows you to adapt the drive to the exact needs of your specific application. As a result project work and costs are subsequently reduced. The easy to use interface reduces training requirements. The integrated SmartStart guides users quickly and efficiently through the setup process, which results in fewer faults due to configuration and parameterization errors.

Freedom to design efficient systems

HVAC drives are built on a flexible system architecture, which allows them to be adapted to specific applications to provide maximum system efficiency. Available in a performance range from 1.1 kW to 1.4 MW the FC102 series can control nearly all standard industrial motor technologies, including permanent magnet motors, copper rotor motors and direct line PM. The frequency converter is designed to work with all common supply voltages: 200, 380-480 V, 525-600 V and 690 V. As a result, system designers, OEMs and end users can connect the drive to their chosen motor and reduce project costs with a solution that performs to the highest standards.

Danfoss VLT HVAC frequency inverter FC 102 platform highlights

- Versatile, flexible, configurable- EMC filters integrated as standard

- Asynchronous & PM motor control

- 9 fieldbuses supported

- Up to 1.4 MW in common voltages

- Unique user interface

- Globally supported

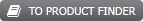

Size and protection class- the perfect fit for Danfoss VLT HVAC drive FC 102 series

All Danfoss VLT® frequency converters follow the same design principle for fast, flexible and fault-free installation and efficient cooling.

Cost saving heat management- In VLT® HVAC Drives the cooling air and the internal electronics is seperated, protecting electronicsfrom contaminants. At the same time it removes heat efficiently which helps to prolong product life, increase the overall availability of the system and reduce faults related to high temperatures.For example, by exhausting heat directly outside it is possible to reduce the size of the cooling system in the panel or switch room. This can be achieved with Danfoss’ panel through cooling system or the extremely efficient back channel cooling concept, that also allows to conduct the heat into the outside of the control room. Both methods make it possible to reduce the initial cost of the panel or switch room. In daily use the benefits are equally clear as the energy consumption related to cooling can be reduced significantly. This means that designers can reduce the size of the air conditioning system, or even eliminate it entirely.

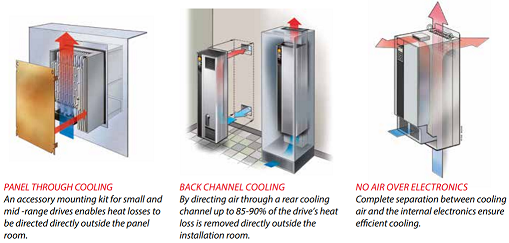

Danfoss VLT HVAC drive FC 102 are equipped with DC chokes that reduce mains interference to a THDi of 40%

Optimize performance and grid protection

Built-in protection as standard- The VLT® HVAC Drive FC102 contains all modules necessary for compliance with EMC standards. A built-in scalable RFI filter minimizes electromagnetic interference. Integrated DC chokes reduce harmonic distortion in the mains network, which increases the lifetime of the DC link capacitors and therefore the drive system’s overall efficiency. The solutions save cabinet space, as they are integrated in the drive from the factory. Efficient EMC mitigation also enables the use of cables with smaller cross-sections, which again reduces installation costs.

Expand grid protection with filter solutions

If needed, Danfoss’ wide range of solutions for harmonic mitigation can provide additional protection, such as the:- VLT® Advanced Harmonic Filter AHF

- VLT® Advanced Active Filter AAF

- VLT® Low Harmonic Drives

- 12-pulse VLT® drives

Provide motor protection with:

- VLT® Sine Wave Filter

- VLT® dU/dt Filter

With this solutions you may achieve optimum performance for your application, even in weak or unstable grids.

Danfoss VLT HVAC inverter FC 102 uses motor cables up to 300m

The design of the VLT® HVAC Drive makes it a perfect choice in applications that require long motor cables. Without needing additional components the drive provides trouble free operation with cable lengths of up to 150 m screened or 300 m unscreened. This allows the drive to be installed in a central control room a distance away from the application without affecting motor performance.

Increased Danfoss VLT HVAC vfd FC 102 series safety

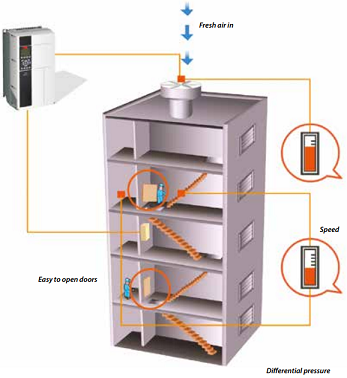

Fire override mode- Activating the function “Fire-mode” within the VLT® drive ensures secure and continued operation within applications such as stair-well pressurisation, car park exhaust fans, smoke exhaust and essential service functions.

Drive bypass- If a drive bypass is available the VLT® HVAC Drive will not only sacrifice itself; it will also bypass itself and connect the motor directly to mains. As a result fan functionality will be maintained after the drive fails, as long as there is power and the motor is functioning. (only available in the USA)

Protect applications and operators- The VLT® HVAC Drive FC 102 is able to provide the STO (Safe Torque Off ) function in compliance with ISO13849-1 PL d and SIL 2, according to IEC 61508 /IEC 62061. In high demand applications this can be expanded with the VLT® Safe Option MCB 140, an external module that provides functions such as Safe Stop 1 (SS1), Safely Limited Speed (SLS) and Safe Maximum Speed (SMS), control of external contactors and safety door monitoring and unlocking.

Nine fieldbuses supported

Increase productivity- With the wide range of fieldbus options the VLT® HVAC Drive can be easily connected to the fieldbus system of your choice. This makes the HVAC Drive a future-ready solution that can easily be expanded and updated if your needs change. Danfoss fieldbus options can also be installed as a plug-and-play solution at a later stage, if the production layout demands a new communication platform. This way, you can be confident that you can optimize your plant without being forced to replace your existing drive system.

BACnet Change of Value (COV)- The standard, passive, BACnet protocol that is embedded in every HVAC drive, can be expanded with the VLT® BACnet Option MCA 109 option. This add-on enables the drive to support COV. As a result the drive will only communicate if pre-defined setpoints are exceeded. By effectively optimizing communication, the MCA 109 reduces the load on the fieldbus enabling more efficient building management.

Energy documentation of Danfoss VLT HVAC drive FC 102 series

VLT® Energy Box software is the most modern and advanced energy calculation tool available. It allows energy consumption calculations and comparisons of HVAC fans, pumps and cooling tower applications driven by Danfoss drives and alternative methods of flow control. The program compares the total operational costs of various traditional systems to operation of the same systems with a VLT® HVAC Drive. With this program it is easy to evaluate the savings by comparing a VLT® HVAC Drive over other types of capacity control systems in both new installations as well as retrofit situations.VLT® Energy Box makes it possible to capture actual energy data from the drives and monitor energy consumption and overall system efficiency.

Energy audit- The VLT® HVAC Drive coupled with Energy Box software enables the package to be used as the Energy Audit equipment for both the estimation and validation of savings.VLT® HVAC Drive can be interrogated remotely for full energy data, making it easy to monitor your energy savings and return on investment. Monitoring via fieldbus often makes energy meters omissible.

Danfoss VLT HVAC inverter FC 102 series has dedicated pump features

The VLT® HVAC Drive is developed in close cooperation with OEMs, contractors, and manufacturers around the world. Each drive contains a wide range of built-in, dedicated features save energy in pump applications.

Embedded pump controller- The Pump Cascade Controller distributes operation hours evenly across all pumps. Wear and tear on individual pumps is therefore reduced to a minimum, extending their lifetime expectancy and reliability considerably.

Vital water supply- If a pipe leaks or breaks, the HVAC Drive can reduce the motor speed to prevent overload, while continuing to supply water a lower speed.

Sleep mode- In situations with low or now flow, the drive enters sleep mode to conserve energy. When the pressure falls below the pre-defined setpoint, the drive starts automatically. Compared to continuous operation this method reduces energy costs and equipment wear and tear, extending the lifetime of the application.

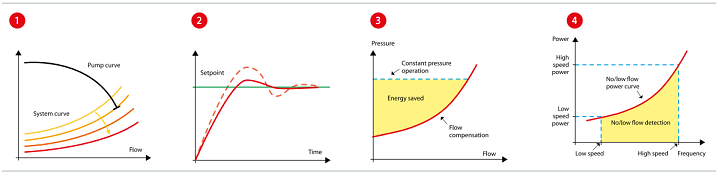

1. Dry Pump Protection and End of Curve

If the pump runs without creating the desired pressure, the drive sets off an alarm or performs another pre-programmed action. This happens for example when a well runs dry or a pipe leaks.

2. Auto tuning of PI controllers

Auto tuning enables the drive to monitor how the system reacts to corrections made by the drive constantly. The drive learns from it and calculates the P and I values, so precise and stable operation is restored quickly.

3. Flow compensation

A pressure sensor mounted close to the fan or pump provides a reference point that enables pressure to be kept constant at the discharge end of the system. The drive constantly adjusts the pressure reference to follow the system curve. This method both saves energy and reduces installation costs.

4. No/low flow

During operation, a pump normally consumes more power the faster it runs. In situations where the pump runs fast, but is not fully loaded, and does not consume adequate power, the drive compensates accordingly. This is a particular advantage when water circulation stops, the pump runs dry or when pipes leak.

Product code list with corresponding models for

Danfoss frequency inverters VLT HVAC Drive FC 102 series

| Item code | Model name |

| 131B4207 | FC-102P1K1T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131B4217 | FC-102P1K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131B4218 | FC-102P2K2T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131B4219 | FC-102P3K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131B3489 | FC-102P4K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131B4220 | FC-102P5K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131B3603 | FC-102P7K5T4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F0427 | FC-102P11KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F6631 | FC-102P15KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F6632 | FC-102P18KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F6629 | FC-102P22KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131B5945 | FC-102P30KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F6630 | FC-102P37KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F0340 | FC-102P45KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F0341 | FC-102P55KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F0342 | FC-102P75KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F0343 | FC-102P90KT4E20H1XGXXXXSXXXXAXBXCXXXXDX |

| 131F0803 | FC-102P1K1T4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131F4733 | FC-102P1K5T4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131B9851 | FC-102P2K2T4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131B9854 | FC-102P3K0T4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131F3134 | FC-102P4K0T4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131F4736 | FC-102P5K5T4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131F4737 | FC-102P7K5T4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131F9848 | FC-102P11KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131F9849 | FC-102P15KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131F9854 | FC-102P18KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131H4949 | FC-102P22KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131H2986 | FC-102P30KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131H2987 | FC-102P37KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131H6031 | FC-102P45KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131H6032 | FC-102P55KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131H4955 | FC-102P75KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131H4956 | FC-102P90KT4E20H1TGXXXXSXXXXAXBXCXXXXDX |

| 131B3526 | FC-102P1K1T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131B4206 | FC-102P1K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131B3532 | FC-102P2K2T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131B4214 | FC-102P3K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131B4215 | FC-102P4K0T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131B4216 | FC-102P5K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131B3611 | FC-102P7K5T4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F0426 | FC-102P11KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F6625 | FC-102P15KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F5456 | FC-102P18KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F6626 | FC-102P22KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F5454 | FC-102P30KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F5451 | FC-102P37KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F6627 | FC-102P45KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F5449 | FC-102P55KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F6628 | FC-102P75KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131F5448 | FC-102P90KT4E20H2XGXXXXSXXXXAXBXCXXXXDX |

| 131B9607 | FC-102P1K1T4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131N5278 | FC-102P1K5T4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131N5275 | FC-102P2K2T4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131N5277 | FC-102P3K0T4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131X6215 | FC-102P4K0T4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131N5279 | FC-102P5K5T4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131G6770 | FC-102P7K5T4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131X2659 | FC-102P11KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131G6771 | FC-102P15KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131G6772 | FC-102P18KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131L7797 | FC-102P22KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131G0881 | FC-102P30KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131G6775 | FC-102P37KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131H7182 | FC-102P45KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131L7798 | FC-102P55KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131G9739 | FC-102P75KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

| 131L0945 | FC-102P90KT4E20H2TGXXXXSXXXXAXBXCXXXXDX |

Download manuals (all parameters)

Danfoss frequency converters (changers)