|

Emotron VFX 2.1 variable frequency drive is ideal for dynamic applications. Due to the new smart 365A Power Electronic Building Blocks (PEBBs) there is up to 30% width reduction in the final drive cabinet.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads  Request additional information and get a price quote Request additional information and get a price quote |

Model range

VFX 2.1 (3 phase 400 V), IP20

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| VFX48-430-20 | 200 / 220 | 344 / 430 | 0-3600 | 500х1036х450 | 14 116,00 € | |

| VFX48-500-20 | 220 / 250 | 400 / 500 | 0-3600 | 500х1036х450 | 16 064,00 € | |

| VFX48-590-20 | 250 / 315 | 472 / 590 | 0-3600 | 500х1036х450 | 19 423,00 € | |

| VFX48-660-20 | 250 / 355 | 528 / 660 | 0-3600 | 500х1176х450 | 21 464,00 € | |

| VFX48-730-20 | 315 / 400 | 584 / 730 | 0-3600 | 500х1176х450 | 25 042,00 € | |

| VFX48-810-20 | 355 / 450 | 648 / 810 | 0-3600 | 730х1036х450 | 28 111,00 € | |

| VFX48-885-20 | 400 / 500 | 708 / 885 | 0-3600 | 730х1036х450 | 29 674,00 € | |

| VFX48-1010-20 | 450 / 560 | 808 / 1010 | 0-3600 | 730х1176х450 | 31 585,00 € | |

| VFX48-1100-20 | 500 / 630 | 880 / 1100 | 0-3600 | 730х1176х450 | 34 674,00 € | |

| VFX48-1300-20 | 560 / 710 | 1040 / 1300 | 0-3600 | (500+500)х1176х450 | 39 484,00 € | |

| VFX48-1460-20 | 630 / 800 | 1168 / 1460 | 0-3600 | (500+500)х1176х450 | 45 227,00 € | |

| VFX48-1710-20 | 750 / 900 | 1368 / 1710 | 0-3600 | (730+500)х1176х450 | 52 764,00 € | |

| VFX48-1820-20 | 800 / 1000 | 1456 / 1820 | 0-3600 | (730+500)х1176х450 | 58 627,00 € | |

| VFX48-2190-20 | 1000 / 1200 | 1752 / 2190 | 0-3600 | (730+730)х1176х450 | 67 840,00 € | |

| VFX48-2550-20 | 1120 / 1400 | 2040 / 2550 | 0-3600 | (500+730+500)х1176х450 | 75 378,00 € | |

| VFX48-2920-20 | 1300 / 1600 | 2336 / 2920 | 0-3600 | (730+500+730)х1176х450 | 86 146,00 € | |

VFX 2.1 (3 phase 690 V), IP20

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| VFX69-002-20 | 0.75 / 1.5 | 1.6 / 2 | 0-3600 | 176x438x267 | 1 753,00 € | |

| VFX69-003-20 | 1.5 / 2.2 | 2.4 / 3 | 0-3600 | 176x438x267 | 1 795,00 € | |

| VFX69-004-20 | 2.2 / 3 | 3.2 / 4 | 0-3600 | 176x438x267 | 1 844,00 € | |

| VFX69-006-20 | 3 / 4 | 4.8 / 6 | 0-3600 | 176x438x267 | 1 894,00 € | |

| VFX69-008-20 | 4 / 5.5 | 6.4 / 8 | 0-3600 | 176x438x267 | 1 950,00 € | |

| VFX69-010-20 | 5.5 / 7.5 | 8 / 10 | 0-3600 | 176x438x267 | 2 021,00 € | |

| VFX69-013-20 | 7.5 / 11 | 10.4 / 13 | 0-3600 | 176x438x267 | 2 210,00 € | |

| VFX69-018-20 | 11 / 15 | 14.4 / 18 | 0-3600 | 176x438x267 | 2 492,00 € | |

| VFX69-021-20 | 15 / 18.5 | 16.8 / 21 | 0-3600 | 176x438x267 | 2 886,00 € | |

| VFX69-025-20 | 18.5 / 22 | 20 / 25 | 0-3600 | 176x438x267 | 3 266,00 € | |

| VFX69-033-20 | 22 / 30 | 26 / 33 | 0-3600 | 220x545x291 | 3 844,00 € | |

| VFX69-042-20 | 30 / 37 | 34 / 42 | 0-3600 | 220x545x291 | 4 448,00 € | |

| VFX69-050-20 | 37 / 45 | 40 / 50 | 0-3600 | 220x545x291 | 4 997,00 € | |

| VFX69-058-20 | 45 / 55 | 46 / 58 | 0-3600 | 220x545x291 | 5 610,00 € | |

| VFX69-250-20 | 200 / 250 | 200 / 250 | 0-3600 | 500x1176x450 | 15 030,00 € | |

| VFX69-300-20 | 250 / 315 | 240 / 300 | 0-3600 | 500x1176x450 | 19 040,00 € | |

| VFX69-375-20 | 315 / 355 | 300 / 375 | 0-3600 | 500x1176x450 | 21 043,00 € | |

| VFX69-400-20 | 315 / 400 | 320 / 400 | 0-3600 | 500x1176x450 | 22 446,00 € | |

| VFX69-430-20 | 315 / 450 | 344 / 430 | 0-3600 | 730x1176x450 | 25 964,00 € | |

| VFX69-500-20 | 355 / 500 | 400 / 500 | 0-3600 | 730x1176x450 | 29 562,00 € | |

| VFX69-595-20 | 450 / 600 | 480 / 600 | 0-3600 | 730x1176x450 | 31 612,00 € | |

| VFX69-650-20 | 500 / 630 | 520 / 650 | 0-3600 | 1100x1176x450 | 34 572,00 € | |

| VFX69-720-20 | 560 / 710 | 576 / 720 | 0-3600 | 1100x1176x450 | 42 569,00 € | |

| VFX69-800-20 | 630 / 800 | 640 / 800 | 0-3600 | 1100x1176x450 | 47 299,00 € | |

| VFX69-905-20 | 710 / 900 | 720 / 900 | 0-3600 | 1365x1176x450 | 53 212,00 € | |

| VFX69-995-20 | 800 / 1000 | 800 / 1000 | 0-3600 | 1365x1176x450 | 59 124,00 € | |

| VFX69-1K2-20 | 900 / 1200 | 960 / 1200 | 0-3600 | 1630x1176x450 | 70 949,00 € | |

| VFX69-1K4-20 | 1120 / 1400 | 1120 / 1400 | 0-3600 | 2000x1176x450 | 82 772,00 € | |

| VFX69-1K6-20 | 1250 / 1600 | 1280 / 1600 | 0-3600 | 2230x1176x450 | 94 597,00 € | |

| VFX69-1K8-20 | 1400 / 1800 | 1440 / 1800 | 0-3600 | 2530x1176x450 | 106 422,00 € | |

| VFX69-2K0-20 | 1600 / 2000 | 1600 / 2000 | 0-3600 | 2830x1176x450 | 118 248,00 € | |

| VFX69-2K2-20 | 1700 / 2200 | 1760 / 2200 | 0-3600 | 3130x1176x450 | 130 072,00 € | |

| VFX69-2K4-20 | 1900 / 2400 | 1920 / 2400 | 0-3600 | 3430x1176x450 | 141 896,00 € | |

| VFX69-2K6-20 | 2000 / 2600 | 2080 / 2600 | 0-3600 | 3730x1176x450 | 153 721,00 € | |

| VFX69-2K8-20 | 2200 / 2800 | 2240 / 2800 | 0-3600 | 4030x1176x450 | 165 546,00 € | |

| VFX69-3K0-20 | 2400 / 3000 | 2400 / 3000 | 0-3600 | 4330x1176x450 | 177 371,00 € | |

VFX 2.1 (3 phase 690 V), IP54

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| VFX69-002-54 | 0.75 / 1.5 | 1.6 / 2 | 0-3600 | 178x512x314 | 1 921,00 € | |

| VFX69-003-54 | 1.5 / 2.2 | 2.4 / 3 | 0-3600 | 178x512x314 | 1 964,00 € | |

| VFX69-004-54 | 2.2 / 3 | 3.2 / 4 | 0-3600 | 178x512x314 | 2 021,00 € | |

| VFX69-006-54 | 3 / 4 | 4.8 / 6 | 0-3600 | 178x512x314 | 2 092,00 € | |

| VFX69-008-54 | 4 / 5.5 | 6.4 / 8 | 0-3600 | 178x512x314 | 2 176,00 € | |

| VFX69-010-54 | 5.5 / 7.5 | 8 / 10 | 0-3600 | 178x512x314 | 2 218,00 € | |

| VFX69-013-54 | 7.5 / 11 | 10.4 / 13 | 0-3600 | 178x512x314 | 2 436,00 € | |

| VFX69-018-54 | 11 / 15 | 14.4 / 18 | 0-3600 | 178x512x314 | 2 795,00 € | |

| VFX69-021-54 | 15 / 18.5 | 16.8 / 21 | 0-3600 | 178x512x314 | 3 126,00 € | |

| VFX69-025-54 | 18.5 / 22 | 20 / 25 | 0-3600 | 178x512x314 | 3 583,00 € | |

| VFX69-033-54 | 22 / 30 | 26 / 33 | 0-3600 | 220x590x295 | 4 153,00 € | |

| VFX69-042-54 | 30 / 37 | 34 / 42 | 0-3600 | 220x590x295 | 4 822,00 € | |

| VFX69-050-54 | 37 / 45 | 40 / 50 | 0-3600 | 220x590x295 | 5 540,00 € | |

| VFX69-058-54 | 45 / 55 | 46 / 58 | 0-3600 | 220x590x295 | 6 145,00 € | |

| VFX69-082-54 | 55 / 75 | 66 / 82 | 0-3600 | 345x1090x312 | 7 225,00 € | |

| VFX69-090-54 | 75 / 90 | 72 / 90 | 0-3600 | 345x1090x312 | 7 982,00 € | |

| VFX69-109-54 | 90 / 110 | 87 / 109 | 0-3600 | 345x1090x312 | 9 084,00 € | |

| VFX69-146-54 | 110 / 132 | 117 / 146 | 0-3600 | 345x1090x312 | 9 869,00 € | |

| VFX69-175-54 | 132 / 160 | 140 / 175 | 0-3600 | 345x1090x312 | 11 029,00 € | |

| VFX69-200-54 | 160 / 200 | 160 / 200 | 0-3600 | 345x1090x312 | 12 605,00 € | |

Built-in DC-choke

With AC drives it is common to use inductors, either on the AC supply side (AC-choke) or in the capacitor DC-link (DC-choke) to reduce AC line harmonics and minimize the stress on the internal power capacitors. An important benefit of using DC-choke instead of AC-choke is that the supply voltage can be fully utilized without substantial voltage drop. Hereby the rated motor power can be maintained when applying an AC drive.Integrated EMC filter

All drives in the series are delivered with a built-in Category C3 EMC-filter as standard. C3 requirements are fulfilled with 80 m motor cable.

Speed controlled cooling fanEmotron FDU and Emotron VFX AC drives have speed controlled fans as standard. Controlling the fan speed in accordance with the cooling needs ensures a stable internal temperature that extends the lifetime of your investment and also reduces noise.Easily accessible power terminalsTo simplify the power supply and motor connections the terminals are integrated in the enclosure and enables cable access from the outside of the unit. Still the IP20/21 protection is achieved when the cable has been connected.Fast and smooth process controlThe built-in PID regulator is used for fast and smooth control of, for example, flow, pressure or temperature. The reference value can be set via an analogue input, via fieldbus communication, or via the control panel. The measured actual value is derived from a process sensor connected to an analogue input or a PT100 input. |

|

Direct torque control for accurate and fast control

With its direct torque control, Emotron VFX is the choice for all dynamic or constant torque applications. Operation is optimized and you are in full control of the process. Emotron VFX protects the operation from interruptions thanks to the very accurate and quick speed and torque control.The torque control reacts extremely quickly and eliminates disturbances due to peak loads, abrupt load changes or incorrectly set ramp times. The fast torque response results in safer, more cost-effective operation, for example of a crane where frequent and critical starts and stops demand instant high torque, or of a crusher where speed quickly needs to be adjusted to changes in load or type of material.

Sensorless speed controller increases efficiency

Emotron VFX has an internal speed controller that increases efficiency. It reacts immediately to load changes that cause deviation in motor speed, and quickly adjusts speed to the set reference value. The controller works without an external feedback and an autotune function reduces set-up time. Encoder feedback (option) can though be applied when higher control accuracy or position measurement is required.Safe and efficient braking

An integrated vector brake function offers rapid and protective braking. No mechanical brakes are required. The braking energy is dissipated through the motor itself, which helps avoid interruptions due to excessive brake voltage. In mill applications, quick and secure stops are often needed for safety or productivity reasons. These are ensured by using the vector brake. For a heavily loaded crane, a brake chopper, available as a factory built-in option, guarantees very rapid but soft braking without any jerky movements. Regenerative braking with active front end technology (AFE) is available as an option, saving considerable energy costs as well as reducing harmonic distortions.Spin start

For loads with high inertia or low friction like large fans and centrifuges the spin start function offers a reliable restarting capability after a power interruption by detecting motor speed and direction of rotation and controlling the load to its requested operational state without unnecessary high current peaks, blown fuses or extended mechanical stress.Dedicated control for pumps and fans save energy with speed control

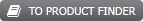

Being able to continuously adapt the operation of your pumps and fans to match demand by controlling motor speed results in considerable energy and maintenance savings, compared to the use of throttling valves or dampers. The latter is like running a car at full throttle while controlling the speed using the brakes. Further energy savings, as well as reduced motor noise, are offered thanks to flux optimization. This function increases motor efficiency by adjusting the output voltage to the actual load, improving the motor’s actual power factor.Sleep function optimizes operation

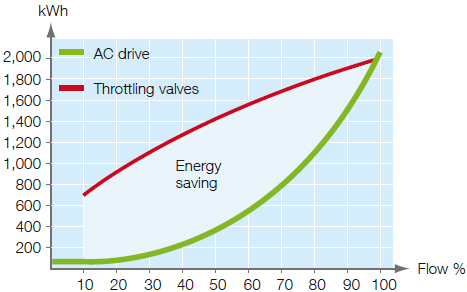

A built-in sleep function optimizes the process by stopping the motor when the built-in PID process regulator determines that it does not need to run in order to keep up the requested level. The motor is restarted as soon as the controlled process so requires. This reduces energy consumption and equipment wear. You can also set the sleep mode to be activated in low flow or no flow situations that are not detected by the PID control, for example due to valves which are closing too slowly. This avoids the pump and motor overheating and energy being wasted. |

|

Speed control offers considerable energy savings. In this pump application, energy consumption is reduced by up to 50% compared to throttling valves. Calculation assumes a 2.2 kW motor. | Energy saving by pausing the motor whenever it does not need to be run in order to keep up the required pressure. The sleep mode can also be activated in low flow situations not detected by the PID control, thus avoiding overheating and energy waste. |

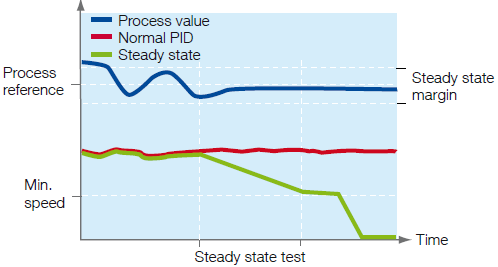

Automatic pump rinsing increases efficiencyEmotron FDU and Emotron VFX AC drives can be set for automatic pump rinsing using a timer. When a pump is running at low speed or standing still, sludge often sticks to the impeller, reducing the pump’s efficiency.With an Emotron FDU or Emotron VFX AC drive, you can set the pump to run at full speed for certain intervals or for a certain time at start-up, before returning to normal operation. This cleans the pump and pipes and increases efficiency. |

|

Multiple control for efficiency and reliability

Using multiple pumps or compressors to keep a constant flow or pressure despite varying demands is a flexible, reliable and cost-efficient method. At all times you only use the number of pumps or compressors needed and thus the amount of energy required. An Emotron FDU or Emotron VFX controls up to seven motors without PLCs or other external equipment. When, for example in a pressure control application, one pump reaches its limit, or when the demand decreases, more pumps are started or stopped in accordance with the determined need. The pressure control is maintained by the built-in PID process regulator. Which pumps to start or stop is decided by the integrated controller, giving them all equal running time. Should one pump or motor break down, the system automatically switches over to the next in line, avoiding unnecessary downtime.Programmable logical and timer functions

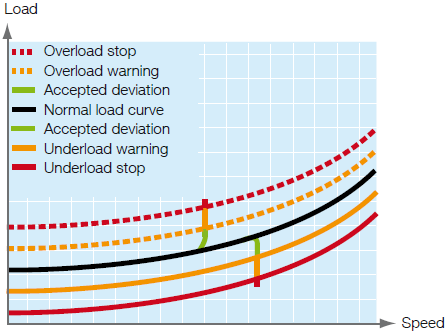

The Emotron FDU/VFX AC drive offers built-in programming blocks, such as logical functions, comparators and timers. This opens the way for customizing functionality according to your requirements. You can, for example, set the AC drive to automatically clean a pump using a timer.Motor load monitor with auto-setA built-in load monitor protects your process against damage and downtime. The load curve of the controlled equipment is monitored across the entire speed range. This is achieved by activating automatic curve identification (Auto-Set) during commissioning.Any over- or underload situation that could cause inefficiency or damage is detected immediately. You can easily set the warning and safety stop levels that allow you to take preventive action before damage occurs. There is no need to worry about dry-running, overheating or blocked pipes. And you will be warned if, for example, your compressor is idling, a fan belt is broken or a valve has not fully opened. The AC drive simply protects the process and makes sure it works as efficiently as possible. |

|

Options

Standard options- IP21 top cover

- Industrial Ethernet communication (Modbus/TCP, EtherCAT, Profinet etc)

- Fieldbus communication (Profibus DP, DeviceNet)

- Serial communication via RS232 or RS485 with Modbus RTU

- Extended digital I/O board

- PTC/PT-100 Motor protection board (PTC + max 3 PT-100)

- Encoder board (TTL (5 V) and HTL (24 V))

- Crane control board

- External control panel

Factory options

- Brake chopper, integrated

- Extended EMC protection (1st environment Category C2)

- Safe stop without a contactor, i.e. Safe Torque Off (STO), for fulfilling machine safety standards EN 13849-1 and EN 62061 requirements

- Brake chopper, integrated

- Extended EMC protection (1st environment Category C2)

- Safe stop without a contactor, i.e. Safe Torque Off (STO), for fulfilling machine safety standards EN 13849-1 and EN 62061 requirements

Other options

- Motor filters (output choke, sinus-filter, common mode filter)

- Active front end for regeneration or low harmonics (only available above 45 kW)

- Brake resistors

- Motor filters (output choke, sinus-filter, common mode filter)

- Active front end for regeneration or low harmonics (only available above 45 kW)

- Brake resistors

Modular drive cabinets with increased power efficiency

Emotron cabinet drives are easily built to preferred power with a new design of modular Power Electronic Building Blocks (PEBBs). Each PEBB is interchangeable and self-monitored.Emotron cabinets builds are now available with:

- Average 30% reduced cabinet width (compared to previous 400V models)

- Smart temp/speed control of DC-powered cabinet fans for optimized fan life time and efficiency

- Cabinet configurator tool for simplified generation of quote and layout

Cabinet designs are based on:

- Standard cabinets with a width of 600mm and 1000mm

- Depth of 600mm

- Height of 2200mm (including 100mm base/plinth and air-outlet)

Secure an efficient operation with state-of-the art air cooled heatsinks with heat pipe technology, communication with all main fieldbuses, remote access and integrated shaft power monitoring.