|

The new inverter series ADV200 represents an innovative concept in drive technology, as a result of the constant technological research and of the experience that the Gefran Group has acquired keeping a constant presence aside that of the major sector players. The new range has been engineered and developed to satisfy the real needs of System Integrators and OEM’s in order to provide them the best innovations and economical competitiveness in the international markets. Based on full mechanical modularity and on a powerful, intuitive and “fully open” programming platform, ADV200 offers absolute integration flexibility with high-end performance in any system architectures of the most advanced automation environments.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

ADV200 industrial series (3 phase 380-500 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| ADV200-1007 | 0,75 | 2.5 | 120x320x235,1 | reduced! | |

| ADV200-1015 | 1,5 | 4.3 | 120x320x235,1 | reduced! | |

| ADV200-1022 | 2,2 | 5.8 | 120x320x235,1 | reduced! | |

| ADV200-1030 | 3 | 7.6 | 120x320x235,1 | reduced! | |

| ADV200-1040 | 4 | 9.5 | 120x320x235,1 | reduced! | |

| ADV200-2055 | 5,5 | 13 | 150x392x250,1 | reduced! | |

| ADV200-2075 | 7,6 | 16.5 | 150x392x250,1 | reduced! | |

| ADV200-2110 | 11 | 23 | 150x392x250,1 | reduced! | |

| ADV200-3150 | 15 | 31 | 180x517x250,1 | reduced! | |

| ADV200-3185 | 18,5 | 38 | 180x517x250,1 | reduced! | |

| ADV200-3220 | 22 | 46 | 180x517x250,1 | reduced! | |

| ADV200-4300 | 30 | 62 | 268x616x270 | reduced! | |

| ADV200-4370 | 37 | 75 | 268x616x270 | reduced! | |

| ADV200-4450 | 45 | 87 | 268x616x270 | reduced! | |

| ADV200-5550 | 55 | 105 | 300x680x325 | reduced! | |

| ADV200-5750 | 75 | 150 | 300x680x325 | reduced! | |

| ADV200-5900 | 90 | 180 | 300x680x325 | reduced! | |

| ADV200-61100 | 110 | 210 | 410x894x359 | reduced! | |

| ADV200-61320 | 132 | 250 | 410x894x359 | reduced! | |

| ADV200-71600 | 160 | 300 | 400x1200x485 | reduced! | |

| ADV200-72000 | 200 | 385 | 400x1200x485 | reduced! | |

| ADV200-72500 | 250 | 460 | 400x1200x485 | reduced! | |

| ADV200-73150 | 315 | 590 | 417x1264x485 | reduced! | |

| ADV200-73550 | 355 | 650 | 417x1264x485 | reduced! | |

Gefran frequency inverter ADV200 series description.

The new inverter series “ADV200” represents an innovative concept in drive technology, as a result of the constant technological research and of the experience that the Gefran Group has acquired keeping a constant presence aside that of the major sector players. The new range has been engineered and developed to satisfy the real needs of System Integrators and OEM’s in order to provide them the best innovations and economical competitiveness in the international markets. Based on full mechanical modularity and on a powerful, intuitive and “fully open” programming platform, ADV200 offers absolute integration flexibility with high-end performance in any system architectures of the most advanced automation environments. The ADV200 are also available in a range of panel-mounted configurations. It is designed as a compact, ready-for-use solution fully compatible with the maximum operating conditions of the drive. Panels are available with power ratings from 90 kW to 1.65 MW with standard input bridge or the “Active Front End” solution, in two main versions Ready to use and Basic.

Gefran drive ADV200 series general characteristics.

Modularity.

An innovative concept of integrated technology that offers full modularity. Mountable side by side and with accessories specifically dedicated to system solutions, ADV200 has been engineered to make installation easy for any operator, both in existing systems and in specific machine solutions, always offering a real reduction of required space in the cabinet and the best manageability.

Fast access.

Structured to offer simple and fast management of the product in any situation of installation and mounting. From the terminal access to the rack assembling of the options, each operation is quick and easy.

Integrated quality.

ADV200 integrates the fundamental devices for an absolute quality level, such as the DC choke that ensures maximum reliability in any conditions of working and the input filter that renders the drive in compliance with the EMC normative EN61800-3.

Programming keypad.

Structured with 2 setting modes Easy and Expert, to satisfy each level of user’s skill and programming needs both for complex or easy installation. A powerful platform but at the same time with a structure of menu/parameters that offers quick understanding, also facilitated by functionality of the keypad and the display. Intuitive navigation and easy start-up function thanks to the “Wizard” tool. ADV200 offers as standard 10 language programming (English, Italian, French, German, Spanish, Polish, Romanian, Russian, Turkish and Portuguese).

- 4 lines display for 21 characters

- Clear alphanumeric text

- Full information of any parameters

- Fast Navigating Keys

- Key for displaying the last 10 parameters that have been changed

- DISP key for rapid display of operating parameters ,

- Upload - Download and storage of 5 complete sets of drive parameters

- Remotable up to 10 meters.

Gefran vfd ADV200 series tools and software.

Applications:

- Parameter configuration of Gefran devices (Instruments, Drives, Sensors)

- Tuning of control parameters with on-line tests and trends

- Management of parameter archive for multiple configuration.

Features:

- Guided product selection

- Simplified settings

- Multiple languages

- Parameter printout

- Creation and storing of recipes

- Network autoscan

- Oscilloscope.

GF_eXpress is the software used to configure the parameters of the automation components, drives and sensors in the Gefran catalogue. The procedures for selecting and configuring parameters are easy and intuitive, thanks to the graphic interface and devices are grouped according to product type and functions. Product searches are performed by means of a context search and a visual selection from among actual images of the products. This makes it possible to have a single library of devices for all Gefran products. All details for configuration of each single device are set out in XML format to facilitate expansion of the catalogue and parameters.

Standard applications.

- Torque Winder (TW) Standard Winding/Un-Winding control, torque control in open-loop or closed-loop with load cell.

- Positioning control (POS) Single axis Standard Positioning with Absolute encoder management.

- Electric line shaft (ELS) Standard Electronic Line Shaft control.

The experience GEFRAN has acquired in the major application sectors has also produced an extensive range of specific and/or custom solutions for managing the most complex configurations in machines.

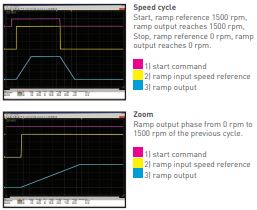

SoftScope.

SoftScope is a software oscilloscope with synchronous sampling (buffered with a minimum sampling time of 1ms). Using SoftScope the user can easily display in a fast way some specific variables, for example commissioning variables, variables to test performance levels achieved or to tune the control loops. SoftScope allows the definition of the following parameters:

- Trigger conditions (e.g. climbing leading edge of a specific signal)

- Recording quality (a multiple of the basic clock at 1ms)

- Recording duration period

- System sizes to be recorded.

"MDPLC" Advanced development environment.

The Motion Drive Programmable logic controller (MDPlc) development environment is a tool for the development of industrial applications based on the ADV200 series of drives. It is an integrated tool that allows writing, compiling, downloading and debugging of the applications. MDPlc allows complete personalisation of the drives according to the application requirements using a “friendly” and powerful graphic interface. The importance of the MDPlc’s performance is particularly evident when defining advanced applications. The primary feature of MDPlc is its ability to create an application code for the drives in assembly language, by compiling the application written in the MDPlc environment with PLC languages in compliance with the IEC 61131-3 international standard. When using an MDPlc application with the ADV200, the drive’s basic functions continue to be executed. Two MDPlc application programs can be stored on the drive. One of the two applications (1 or 2) is enabled via a parameter.

The languages that can be used to program specific custom applications are:

- Instruction List (IL)

- Structured Text (ST)

- Ladder Diagram (LD)

- Function Block Diagram (FBD)

- Sequential Flow Chart (SFC)