|

Lenze 8400 HighLine frequency inverters, for easily controlled motion and positioning, help you stay on top of the situation. Particularly suitable for: rotary indexing tables or warehousing systems in the field of intralogistics, bag form fill and seal machines in the packaging industry.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads  Request additional information and get a price quote Request additional information and get a price quote |

Model range

8400 HighLine machinery series (1 phase 230 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| E84AVHCE2512SX0 | 0.25 | 1.7 | 70x165x199 | 572,00 € | |

| E84AVHCE3712SX0 | 0.37 | 2.4 | 70x165x199 | 612,00 € | |

| E84AVHCE5512SX0 | 0.55 | 3 | 70x215x199 | 650,00 € | |

| E84AVHCE7512SX0 | 0.75 | 4 | 70x215x199 | 707,00 € | |

| E84AVHCE1122SX0 | 1.1 | 5.5 | 70x270x199 | 792,00 € | |

| E84AVHCE1522SX0 | 1.5 | 7 | 70x270x199 | 878,00 € | |

| E84AVHCE2222SX0 | 2.2 | 9.5 | 70x270x199 | 994,00 € | |

8400 HighLine machinery series (3 phase 400 V)

| Model | Capacity, kW |

Current, A |

Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|

| E84AVHCE3714SX0 | 0.37 | 1.3 | 70x215x199 | 792,00 € | |

| E84AVHCE5514SX0 | 0.55 | 1.8 | 70x215x199 | 878,00 € | |

| E84AVHCE7514SX0 | 0.75 | 2.4 | 70x215x199 | 994,00 € | |

| E84AVHCE1124SX0 | 1.1 | 3.2 | 70x270x199 | 1 127,00 € | |

| E84AVHCE1524SX0 | 1.5 | 3.9 | 70x270x199 | 1 260,00 € | |

| E84AVHCE2224SX0 | 2.2 | 5.6 | 70x270x199 | 1 433,00 € | |

| E84AVHCE3024SXS | 3 | 7.3 | 70x270x199 | 1 604,00 € | |

| E84AVHCE4024SX0 | 4 | 9.5 | 140x270x199 | 1 777,00 € | |

| E84AVHCE5524SX0 | 5.5 | 13 | 140x270x199 | 2 083,00 € | |

| E84AVHCE7524SX0 | 7.5 | 16.5 | 140x325x199 | 2 635,00 € | |

| E84AVHCE1134SX0 | 11 | 23.5 | 140x325x199 | 3 247,00 € | |

| E84AVHCE1534SX0 | 15 | 32 | 140x325x199 | 4 298,00 € | |

| E84AVHCE1834VX0 | 18.5 | 40 | 205x350x250 | 5 062,00 € | |

| E84AVHCE2234VX0 | 22 | 47 | 205x350x250 | 5 443,00 € | |

| E84AVHCE3034VX0 | 30 | 61 | 250x450x250 | 6 304,00 € | |

| E84AVHCE3734VX0 | 37 | 76 | 250x450x250 | 7 355,00 € | |

| E84AVHCE4534VX0 | 45 | 89 | 250x450x250 | 8 404,00 € | |

Lenze vfd 8400 Highline series operating modes.

An inverter enables energy-efficient operation of a system in virtually all application cases. The various operating modes, which can be created by making just a few simple settings, facilitate this. The following characteristics and corresponding specifications listed on the following pages can be used to calculate the optimum operating mode during the project planning phase.

Standard setting of Lenze drive 8400 Highline series.

In its initial state when delivered, the inverter is set up for basic operation with a three-phase AC motor with V/f control. When operated in this mode, the rated torque of the motor is available in a setting range up to 50 Hz.

Operation with inverter-optimised MF motors.

Large setting ranges and optimum operation at the rated torque: these are the strengths of the MF motor when used in combination with an inverter. The motors are optimized for a setting range up to 120 Hz. Compared to conventional 50Hz operation, the setting range increases by 250 %. It is quite simply not possible for a drive to be operated any more efficiently in a machine.

Operation with low loads.

This operating mode can be used for various applications, e.g. for fans and pumps: In fan and pump applications, the load behavior follows a squarelaw characteristic depending on the speed. Often, an overload capacity of 120% is sufficient. This serves to operate the inverter during operation with increased power, i.e. the inverter can be dimensioned one power size smaller. The square-law characteristic which corresponds to the load behavior can be set in the inverter.

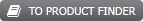

VFC-eco energy saving mode on Lenze frequency inverter 8400 HighLine series.

The Inverter Drives 8400 make energy saving especially easy with the "VFC eco" function. Particularly in the partial load operational range, this function significantly reduces energy requirements. Combined with the new L-force MF three-phase AC motors, this drive solution impresses with the maximum energy efficiency of a Lenze BlueGreen solution. The "VFC eco" mode adjusts the magnetising current of a motor intelligently to actual requirements. This is particularly useful in partial load operational range, as this is precisely where three-phase AC motors need to be supplied with a greater magnetising current than the operating conditions actually require. The "VFC eco" mode allows losses to be reduced so much that savings of up to 30% can be achieved. Energy efficiency can then be increased even further with the MF three-phase AC motors. These motors have been specifically designed for operation with frequency inverters. They operate at 120 Hz instead of 50 Hz, as 4-pole three-phase AC motors are at their most efficient at this frequency.

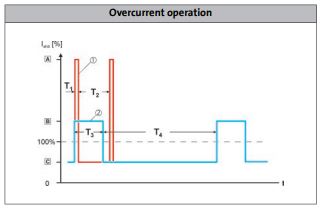

Lenze drive 8400 HighLine series overcurrent operation.

The inverters can be driven at higher amperages beyond the rated current if the duration of this overcurrent operation is time limited.Two utilization cycles with a duration of 15 s and 180 s are defined. Within these utilization cycles, an overcurrent is possible for a certain time if afterwards an accordingly long recovery phase takes place. For both utilization cycles, a moving average is determined separately. The adjacent diagram shows both cycles: 15 s in red and 180 s in blue. The overload times tol are 3 s (T1 ) and 60 s (T3 ) respectively, the corresponding recovery times tre are 12 s (T2 ) and 120 s (T4 ) respectively. The following tables show the resulting maximum output currents. Monitoring of the device utilization (I x t) activates the set error response (trip or warning if one of the two utilization values exceeds the limit of 100 %.

Switching frequencies.

On an inverter, the term "switching frequency" is understood to mean the frequency with which the input and outputs of the output module (inverter) are switched. On an inverter, the switching frequency can generally be set to values between 2 and 16 kHz, whereby the selection is based on the respective power output. Since losses (in the form of heat) can be generated when switching the modules, the inverter can provide a higher output current at a switching frequency of 2 kHz. In addition to this, it is also important to differentiate between operation at a fixed switching frequency and a variable switching frequency, whereby the switching frequency is automatically reduced based on the output current here. The data for operation at increased output is permitted for operation at a switching frequency of 2 or 4 kHz and in an ambient temperature of max. 40 0 C.