|

The Water & Wastewater and Building Automation industries are two key ingredients in our everyday lives and yet so often go unnoticed. In fact, the only time most people become aware of them is when a problem arises somewhere along the line. VACON® 100 Flow is designed to ensure pump and fan solutions control air- and waterflow quietly, efficiently and without interruptions.

Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

Vacon 100 Flow series, voltage 208-240 V (3 phase)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| VACON0100-3L-0003-2-flow | 0,55 | 3.7 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0004-2-flow | 0,75 | 4.8 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0007-2-flow | 1,1 | 6.6 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0008-2-flow | 1,5 | 8 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0011-2-flow | 2,2 | 11 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0012-2-flow | 3 | 12.5 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0018-2-flow | 4 | 18 | 0,1-3000 | 144х419х214 | reduced! | |

| VACON0100-3L-0024-2-flow | 5,5 | 24 | 0,1-3000 | 144х419х214 | reduced! | |

| VACON0100-3L-0031-2-flow | 7,5 | 31 | 0,1-3000 | 144х419х214 | reduced! | |

| VACON0100-3L-0048-2-flow | 11 | 48 | 0,1-3000 | 195х557х229 | reduced! | |

| VACON0100-3L-0062-2-flow | 15 | 62 | 0,1-3000 | 195х557х229 | reduced! | |

| VACON0100-3L-0075-2-flow | 18,5 | 75 | 0,1-3000 | 237х660х259 | reduced! | |

| VACON0100-3L-0088-2-flow | 22 | 88 | 0,1-3000 | 237х660х259 | reduced! | |

| VACON0100-3L-0105-2-flow | 30 | 105 | 0,1-3000 | 237х660х259 | reduced! | |

| VACON0100-3L-0140-2-flow | 37 | 143 | 0,1-3000 | 290х966х343 | reduced! | |

| VACON0100-3L-0170-2-flow | 45 | 170 | 0,1-3000 | 290х966х343 | reduced! | |

| VACON0100-3L-0205-2-flow | 55 | 208 | 0,1-3000 | 290х966х343 | reduced! | |

| VACON0100-3L-0261-2-flow | 75 | 261 | 0,1-3000 | 480х1150х365 | reduced! | |

| VACON0100-3L-0310-2-flow | 90 | 310 | 0,1-3000 | 480х1150х365 | reduced! | |

Vacon 100 Flow series, voltage 380-500 V (3 phase)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| VACON0100-3L-0003-5-flow | 1,1 | 3.4 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0004-5-flow | 1,5 | 4.8 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0005-5-flow | 2,2 | 5.6 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0008-5-flow | 3 | 8 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0009-5-flow | 4 | 9.6 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0012-5-flow | 5,5 | 12 | 0,1-3000 | 128х328х190 | reduced! | |

| VACON0100-3L-0016-5-flow | 7,5 | 16 | 0,1-3000 | 144х419х214 | reduced! | |

| VACON0100-3L-0023-5-flow | 11 | 23 | 0,1-3000 | 144х419х214 | reduced! | |

| VACON0100-3L-0031-5-flow | 15 | 31 | 0,1-3000 | 144х419х214 | reduced! | |

| VACON0100-3L-0038-5-flow | 18,5 | 38 | 0,1-3000 | 195х557х229 | reduced! | |

| VACON0100-3L-0046-5-flow | 22 | 46 | 0,1-3000 | 195х557х229 | reduced! | |

| VACON0100-3L-0061-5-flow | 30 | 61 | 0,1-3000 | 195х557х229 | reduced! | |

| VACON0100-3L-0072-5-flow | 37 | 72 | 0,1-3000 | 237х660х259 | reduced! | |

| VACON0100-3L-0087-5-flow | 45 | 87 | 0,1-3000 | 237х660х259 | reduced! | |

| VACON0100-3L-0105-5-flow | 55 | 105 | 0,1-3000 | 237х660х259 | reduced! | |

| VACON0100-3L-0140-5-flow | 75 | 140 | 0,1-3000 | 290х966х343 | reduced! | |

| VACON0100-3L-0170-5-flow | 90 | 170 | 0,1-3000 | 290х966х343 | reduced! | |

| VACON0100-3L-0205-5-flow | 110 | 205 | 0,1-3000 | 290х966х343 | reduced! | |

| VACON0100-3L-0261-5-flow | 132 | 261 | 0,1-3000 | 480х1150х365 | reduced! | |

| VACON0100-3L-0310-5-flow | 160 | 310 | 0,1-3000 | 480х1150х365 | reduced! | |

Taking care of the essentials with Vacon frequency inverter 100 Flow series.

The Water & Wastewater and Building Automation industries are two key ingredients in our everyday lives and yet so often go unnoticed. In fact, the only time most people become aware of them is when a problem arises somewhere along the line. VACON® 100 Flow is designed to ensure pump and fan solutions control air- and waterflow quietly and effectively.

Expertise in the field.

VACON® 100 FLOW builds on a long and illustrious track record in the industry. Vacon has produced a number of significant innovations ever since the company’s founding in 1993. 1995 saw us introduce a Multipump application, which has since been updated to include autochange. VACON 100 Flow further develops Multimaster technology, first introduced in 2002, to provide functionalities that significantly extend flow systems’ lifecycle and operational costs. VACON® AC Drives are typically able to reduce energy costs by as much as 30% in pump and fan applications, usually offering a return on investment within a year of purchase compared to conventional control schemes.

Going with the flow.

Pumps and fans control the flow of water and air through the pipes, vents and waterways that are often out of sight, and yet remain central to our lives. Like in so many industrial processes, AC drives optimize these systems and make sure that processes use as little energy as possible. Pumping process water, cooling water and other fluids usually requires that pressure remains constant despite varying demand. VACON 100 Flow comes equipped with a number of innovative functions that ensure you achieve this.

24/7 service and support.

When it comes to flow control processes, it’s critical for systems to run smoothly at all times. Since Vacon is the world’s leading company that’s whole focus is on AC drive solutions, it’s only right that our aftermarket product care is second to none. We offer services that ensure products remain effective for as long as possible, so that repairs and downtime are kept to the bare minimum.

Intelligent process control with Vacon drive 100 Flow series.

VACON® 100 FLOW is an AC drive dedicated to improving flow control in Water & Wastewater and Building Automation applications. It combines the core functionality of VACON® 100 with dedicated functions that are specifically designed with flow control application processes in mind. VACON 100 FLOW is available in a number of frame sizes with either IP21/UL Type 1 or IP54/UL Type 12 approved enclosures. It has a power range of 0.55 kW/0.75 HP to 160 kW/250 HP and a voltage range of 230 V to 500 V.

Dedicated functionality.

VACON 100 FLOW places an emphasis on userfriendliness and functionalities created for use in pump & fan applications. We have used our extensive experience in the field to handpick all the features that are best suited to the application requirements and putting them in one dedicated product. For instance, PID control, which comes as standard eliminates the need for an external controller, with a built-in pressure/flow controller that uses a sensor to ensure the drive will run at the correct speed. This is useful when reacting to fluctuations in demand.

Application menus for water and HVAC.

A StartUp Wizard and Quick Setup mode make it easy for users to select the relevant parameters and monitoring values. Unique application menus guide the user through a quick and easy installation and commissioning, with all the relevant parameters presented to them without the need to navigate a long list of parameters. StartUp Wizard and Quick Setup mode can be activated either through the detachable keypad, or by using VACON® Live, Vacon’s online PC programming tool for AC drives.

Connect to your control system.

Vacon equips its standard AC drives with built-in Ethernet, and VACON 100 FLOW is no different in this respect. This feature means that no additional options or gateways are needed to communicate with process automation. It also provides access for commissioning and maintenance through VACON Live and makes local or remote monitoring possible.

Built to last without interruption.

Unplanned downtime is a problem for all applications, not least pump and fan systems, which is why it is important that components have as long a lifecycle as possible. VACON 100 Flow uses electrolytic-free DC link technology which guarantees users the longest possible lifecycle and availability. By avoiding the need to replace electrolytic capacitors — that often wear out over time — interruptions and costs are kept to a minimum.

Vacon vfd 100 FLOW series multipump control solutions.

Vacon has 20 years of innovations with pump and fan solutions to work with, including pump and fan solutions which ensure that users get the best functionality and cost-efficiency out of their process. We are able to offer three Multipump control solutions, each of which offer unsurpassed control of flow and pressure. Demand for water or ventilation fluctuates throughout the course of a day. For instance, demand for running water in a major city usually peaks in the morning, as a great number of inhabitants are in the shower preparing for the working day. Conversely, in the middle of the night next to no water is being used. By using several pumps as opposed to a single one, higher redundancy and efficiency is achieved since the load is lightened by being spread across several pumps. It also makes for greater reliability – if one pump fails, the others can take on its load.

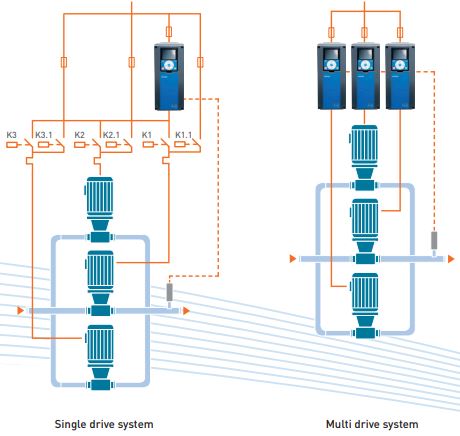

Single drive system.

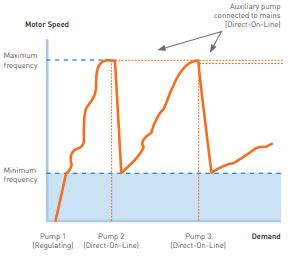

Multipump control is a single-drive solution in which one AC drive controls the leading pump. If the need for capacity exceeds the capabilities of the pump, additional fixed-speed pumps can be connected online or with a soft starter. You can choose between fixed setups and solutions in which the leading and auxiliary pumps alternate in roles to equalize wear and tear.

Multidrive systems.

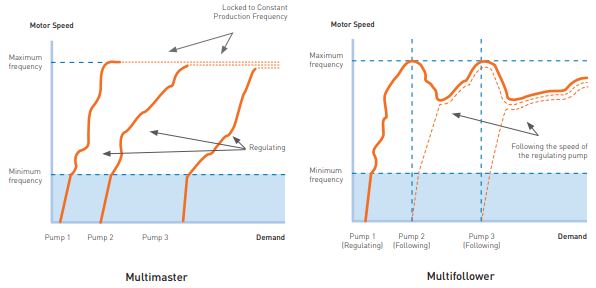

Multimaster technology ensures that each pump is controlled by its ‘own’ AC drive. As demand increases, the leading drive locks into full speed until its capacity is exceeded, at which point the excess load is transferred to the next drive in the series. This method ensures pumps start and stop smoothly, and reduces the need for additional control wiring, motor protection relay and contactors. Multifollower mode follows the same principle of Multimaster in that each pump is controlled by a designated AC drive. Where this system differs is that, as demand increases and the lead drive’s capacity is exceeded, several drives are brought into operation. This ensures that all pumps run at the same operating speed, reducing noise and general stress, thus improving reliability.