PDC inverters are fully digital controllers universally useable for machine and systems applications. They offer machine builders numerous features at a very favorable price. Simple programming of PDC inverters allows set up without extensive training. Machines with motor speeds controlled by PDC inverters demonstrate increased overall efficiencies and flexibility resulting in substantially enhanced productivity.

A key feature of the PDC line is immediately visible:

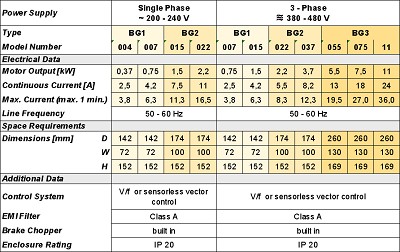

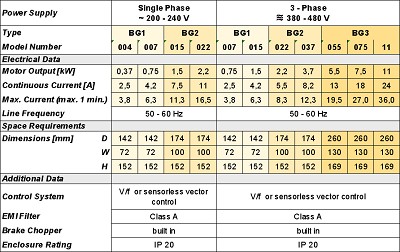

The inverters are of uncommonly compact design allowing for cost and space saving panel installation. The largest unit for a motor output of 11 kW requires only 5.7 dm³ installation space. Because it is acceptable to install the inverters side-by-side, if the electrical panel temperature does not exceed 40 Cº, even more panel space can be saved.

1) Compact Design with Outstanding Features

Compact designs must not limit functionality. PDC inverters are offered in 3 Types for motor outputs from 0.37 kW to 11 kW and incorporate built in EMI filters, PID control and simple PLC functions. Even a brake chopper function is integrated. Different brake resistors are available as optional equipment.

2) All-Purpose

The PDC line is multifunctional with various connection possibilities. Six digital and two analog inputs as well as two digital and one analog output allow multiple ways of integrating the inverters into control and drive systems. Inverters can also communicate through a RS 485 serial interface in “MODBUS protocol” and optionally available plug-in modules allow integration to additional field bus protocols.

3) Fully Digital Electronics

Fully digital electronics do not only offer a great value but shine with short monitoring and cycle times for quick override on highly dynamic drives. Besides the conventional V/f motor characteristics control users can also select a sensorless vector speed control. This selection assures outstanding control characteristics without incurring the high cost of an encoder to establish actual speeds..

4) Simple Parameterization

For minimal space and cost PDC inverters are not equipped with built in keypads. Parameterization of desired inverter settings is done through an optional keypad or – already economical at relatively small production volumes – PC software. PDC inverters can easily be adapted to requirements for various applications. “Auto-Tuning” function even assures self-adjustment of control parameters.

5) An All-Purpose, Inexpensive Inverter

With all its standard features a wide variety of possible applications become technically and economically feasible for an all-purpose, inexpensive inverter. PDC’s can be used for all applications in standard and special machine building industries. ABM Greiffenberger sees focal points in the textile machine industry, controlled drives for packaging machines and transport conveyors respectively augers.

6) Basis for Custom Drive Solutions

The PDC line completes ABM Greiffenberger’s Inverter Program. Furthermore available are types CDA/CDB for highly demanding applications and MDC for decentralized motor control (mounted on motor). Beyond three inverter lines, ABM Greiffenberger as a systems integrator can supply complete electrical drive systems designed and built in house.

7) High Grade Drive Systems from a Single Source

Besides top notch quality and functionality of components, technical support is of utmost importance – starting with comprehensive sales advice of potential customers over jointly defining drive specifications with customers, start up to all-out after-sales-service every facet is covered. It goes without saying that the same comprehensive support is offered for the configuration of drive systems controlled with PDC inverters.

8) Individual Drive Solutions optimize Plants and Machinery

ABM engineers have long time experience in designing drive systems and assuring that each drive is exactly tailored to the requirements of an individual application. In this manner ABM Greiffenberger developed numerous complete drive solutions for the most demanding applications on textile machines, overhead cranes and battery powered material handling vehicles. Our customers are well known companies with a need for individual drive solutions that help optimize output, functionality and quality of their plants and machinery.