Many truck manufacturers are fitting auxiliaries with electric drives which expedites the hybridisation of the vehicles in order to maximise efficiency and to meet the increasingly strict emission regulations. At the eCarTec, ABM Greiffenberger will present a range of electric motors which is perfectly suited for this task. Moreover, the company will also present mobile traction drive units for light electric vehicles at the trade fair.

The future emission regulations – keyword EURO 6 - are forcing the manufacturers of buses and trucks to radically change their drive technologies. In many cases, the further optimisation of the combustion engines is no longer enough to meet the requirements of the standards. A reasonable measure to save energy and reduce emissions is the electrification of auxiliaries such as hydraulic pumps, power steering pumps, air compressors, fans and generators. At the moment, these auxiliaries are normally powered by the diesel engine, and the demand is adjusted by a high-loss flow control valve.

Direct electrical drive for auxiliaries

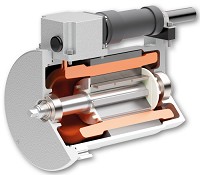

A direct drive with controlled electric motors prevents these losses. It consumes energy only if power is actually required, and it can be optimally adjusted to the respective process via speed control. The permanently excited synchronous motors of the SINOCHRON range which were developed by ABM are ideal for this task. Even under rough ambient conditions with vibrations and high temperatures, as prevailing in automotive and utility vehicle applications, these motors are convincing with fail-safe operation and a high durability. One of the main reasons for this is the special rotor design with internal high-performance magnets.

The SINOCHRON motors are compact and operate with a high efficiency. They are available in the power spectrum from a few 100 W up to 10 kW, in different sizes and lengths. The special design of the rotor with the distinct poles and the distributed stator winding enables smooth running, no noteworthy cogging torque, and, due to the sinusoidal magnetic flux distribution, a sensorless controlled operation of the machine from zero speed up to RPMs of more than 10,000. Another great argument for the use of SINOCHRON drives in the very cost-conscious automotive industry: the simple layout of the motors and the automated manufacture at ABM Greiffenberger are creating the prerequisites for economic solutions for the electrification and hybridisation of utility vehicles.

Driving pleasure and efficiency: 15 kW traction motor

In addition to this range of motors, ABM Greiffenberger also presents a 15 kW traction motor for smaller electric vehicles of the class L7e at the eCarTec. The design of the 15 kW traction motor is ideal for the axially parallel installation on a differential gear. Thanks to high power density and efficient air cooling, this drive achieves efficiencies of up to 93 %. The maximum torque of 130 Nm enables dynamic acceleration and a high driving pleasure. The large field weakening range of the motors enables a high climbing power and fast driving without manual gearbox. With that, ABM Greiffenberger positions itself at the eCarTec as a partner of the automotive industry when it comes to the electrification and hybridisation of vehicle drives. In doing so, the developers at the company are able to resort to extensive experience in the conception of drive solutions for safety-relevant and mobile solutions.