Table of content:

- How does a frequency inverter work?

- How to choose a variable frequency drive?

- How to connect the frequency inverter?

- How to configure the frequency inverter?

- How to start the variable frequency drive?

- How to check the VFD?

- How many years does a frequency inverter last?

- How to maintain a frequency inverter?

- What are the requirements for installation of VFD?

- What are the advantages of using a frequency inverter?

The usage of frequency inverter in combination with asynchronous motors considerably increases their possibilities, makes them more cost effective, improves controllability and expands the automation possibilities. This is why frequency inverters have been increasingly implemented in the last few years with the appearance of sufficiently powerful and reliable variable frequency drives on the market.

However, as this equipment is still quite new and rarely used on the Russian market, most potential customers have questions about the choice of equipment, its implementation, maintenance and operation. Specialists of our company have prepared the most frequent questions, which customers face while choosing such equipment, so acquaintance with them will help you to make the right, weighted and optimal decision.

1. How does a frequency inverter work?

The principle of a frequency inverter is very simple. It is not complicated to implement with modern electronics. Most frequency inverters are based on a double-conversion scheme which implies:

- rectification of mains voltage;

- stabilisation of the supply voltage;

- generation of the output voltage with a set frequency and amplitude, which is fed to the motor power contacts.

Apart from the conversion electronics, the unit is equipped with a control module, indication system, protection against overloads and other emergencies.

Some models have remote control capability as well as one or more sensors for feedback control.

2. How to choose a variable frequency drive?

A variable frequency drive is selected on the basis of such key characteristics as:

- motor power;

- speed control range;

- number of phases;

- ability to connect external sensors;

- type of control system for the operation of the equipment.

If you do not want to know exactly how to choose a frequency inverter, it is best to inform the supplier of these parameters and of the system for which it is being purchased. For example, it may be a pumping system, a ventilation system, or a machine tool motor.

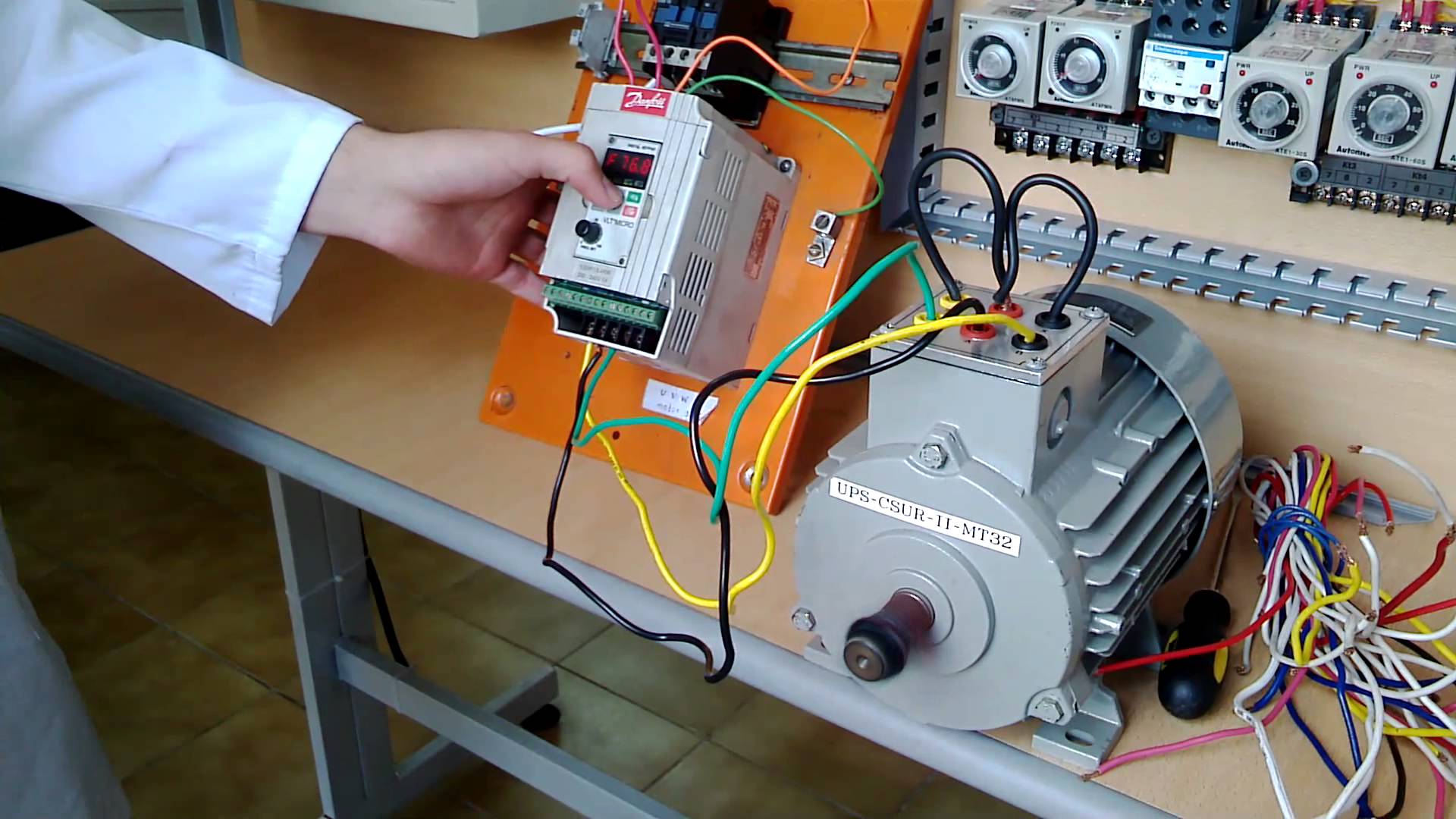

3. How to connect the frequency inverter?

A detailed diagram of how to connect the motor to the variable frequency drive is included in the documentation of the device and is not too complicated for a specialist. If it is a single-phase VFD for domestic use, it can be connected by a home handyman with wiring experience. For single-phase, the connection involves two inputs and two motor outputs; for three-phase, it involves four power inputs and three or four motor outputs, depending on which circuit is used to power the motor.

It may also be necessary to connect a remote control unit, if it is intended by the design, and sensors, if the frequency inverter is controlled by feedback. Please note that this equipment should only be connected to an industrial system by a qualified person with the necessary authorisation to carry out such electrical work.

4. How to configure the frequency inverter?

The frequency inverter tuning technology depends on the type and capabilities of the frequency inverter and can be performed by:

- for simple frequency inverters by selecting the menu operation mode using the controls;

- for control of powerful devices in complex systems with feedback - via computer and special software;

- for frequency controllers operating in feedback systems, additional equipment may be required to fine-tune the differential and integral feedback components.

A user manual will be supplied with the equipment, showing how to adapt it to suit the application, but in some cases the assistance of a qualified engineer with experience in setting up such equipment may be necessary.

5. How to start the variable frequency drive?

Once the system is assembled and configured, there is no problem with how to turn the variable frequency drive on or off. As a rule, starting and stopping modes of such systems are preset during the initial setup of the equipment, and their activation in normal mode is no more complicated than starting an electric motor with an ordinary starter.

6. How to check the VFD?

The function of the frequency inverter should be checked after the purchase of the VFD and only after the system has been assembled and configured. In complex industrial systems, the minimum and maximum declared speed is checked, the motor torque is measured at different frequencies, the temperature of the equipment is assessed and the accuracy of the indication of the operating parameters is evaluated.

The answer to the question of how to check a frequency inverter in low-power domestic applications is much simpler. The frequency control limits, reversing function, and operation of the feedback sensor, if connected, are checked. Most variable frequency drives have a built-in self-diagnostic and monitoring system, so in case of supply voltage deviation, short circuit, motor jamming and other abnormal situations

7. How many years does a frequency inverter last?

Frequency inverters are based on a state-of-the-art electronic base, which usually has a service life of at least 10-15 years if the operating conditions are observed and timely maintenance is carried out. Also most VFDs, especially those with high power, are fully repairable, and repairs can be carried out either by replacing modules or by replacing individual components that have failed.

In addition, these units come with a long warranty period, during which all factory defects are detected. Given this long service life, the only time it may be necessary to replace the unit is when an upgrade is required, such as the replacement of a motor or a higher degree of automation.

8. How to maintain a frequency inverter?

Generally there are no specific requirements for the maintenance of the frequency inverter and it is performed in accordance with the routines approved in the company. Usually variable frequency drive maintenance is carried out at regular intervals, e.g. once in six months or once a year. In the course of such maintenance, the following is carried out:

- a visual inspection of the components, e.g. to detect the absence of blown capacitors, darkening or charring of conductors on the circuit boards;

- The high-power electronics heat sinks are checked for tightness, and if thermal paste is used, it is replaced as thermal conductivity deteriorates;

- the enclosure is cleaned from dust;

- self-diagnostics is performed, if available.

Based on the results of the inspection, a decision is taken whether to continue operation or whether repairs are required.

9. What are the requirements for installation of VFD?

The installation requirements are stated in the documentation. In general, the installation requirements include the ambient temperature, dust levels, humidity and the absence of corrosive gases. The variable frequency drive can be mounted in an electrical cabinet or in a separate enclosure and is often installed close to the actuator, e.g. in a machine housing for retrofitting. For heavy-duty units, an additional requirement may be the need for forced ventilation or free air access to the enclosure where the equipment is installed.

A further requirement that must be fulfilled is the maximum cable length for connecting the load. In general, the installation conditions for the frequency inverter do not differ much from those for any other installation of this type of electrical equipment.

10. What are the advantages of using a frequency inverter?

The advantages and additional features of installing a frequency inverter in a motor control system are many. Here we will only mention the main ones:

- maximum controllability of the system;

- easy reversing of the motor;

- setting of motor start and stop modes;

- considerable energy savings when working at partial capacity;

- easy automation of the system;

- protection of the electric motor from emergency situations.

The list of key benefits may vary depending on the system application, the mode of operation and the equipment capacity, while the economic effect is determined for each specific solution.

If you have any additional questions that you would like an answer to before purchasing such equipment, you can always ask our specialists, as well as get their help in choosing and configuring the optimal model of frequency inverter for your task.