Table of content:

- What is required to repair frequency inverters

- Typical breakdowns of variable frequency drives and how to rectify them

Modern frequency inverters are sophisticated but robust electronic devices, which nevertheless sometimes fail or require periodic maintenance.

The most common causes of failure of frequency inverters that control motors include:

- factory defects in the components of the frequency inverter and defects in the assembly technology. This usually occurs at the start of operation and is repaired under warranty by the manufacturer or retailer;

- harsh operating conditions. Quite often such equipment is operated under conditions that may differ from those recommended by the manufacturer. This leads to heavier duty operation of the electronic components and their failure. These include operation in conditions of high humidity, dusty conditions, high or low temperature variations outside the recommended range, corrosive gases and particles in the ambient air;

- poor quality power supply. One of the most common causes of frequency inverter failure, which is mainly due to supply voltage instability and frequent power fluctuations that the built-in protection cannot cope with;

- operation at excessive power. Occurs when making mistakes in equipment selection or trying to save money by knowingly selecting a frequency inverter that operates at its power limit;

- human error. These may include errors in the installation of the inverters, incorrect setting of the operating mode, and failure to observe the operating rules for such equipment.

Whatever the cause of the failure, you will need to have your frequency inverters repaired, as in most cases it will be much cheaper to restore performance than to buy a new unit.

What is required to repair frequency inverters

What is required to repair frequency inverters

The repair of any frequency inverter requires not only the involvement of a qualified technician in the field of repair of electronic equipment, but also the appropriate workplace equipment. If you are planning to carry out the repair of frequency inverters in-house, the number of units is large enough or your company maintains such systems at other sites, then you will need to provide a workplace with such additional equipment:

- load motor for testing the unit;

- three-phase AC power supply with different voltages depending on the models to be serviced;

- load resistors;

- multimeter and oscilloscope;

- feedback sensors or simulators of their signals;

- a personal computer or laptop to operate the software supplied with most frequency inverter models;

- а soldering station, a set of radio electronic components and tools for repairing radio electronic products.

In other words, in order to service and repair such complex electrical products yourself, a certain amount of capital investment in the equipment of a repair bench is required. Therefore, before deciding to carry out your own maintenance and repair of such expensive equipment as frequency inverters, you should estimate the cost of equipping the workplace and paying a qualified electronic engineer.

Typical frequency inverter breakdowns and remedies

All breakdowns of this type of equipment, which result in both complete inoperability and abnormal operation, can be divided into three large groups:

- Software errors. Generally associated with incorrect programming of operating modes or firmware failures. The cheapest type of fault to correct, which involves either re-flashing the controller or correcting programming errors;

- Failure of the unit's electronic components. This involves a complex diagnostic procedure, identifying the faulty component and the cause of the fault. May require extensive diagnostics, using sophisticated electronic instruments and testing the operation in various modes;

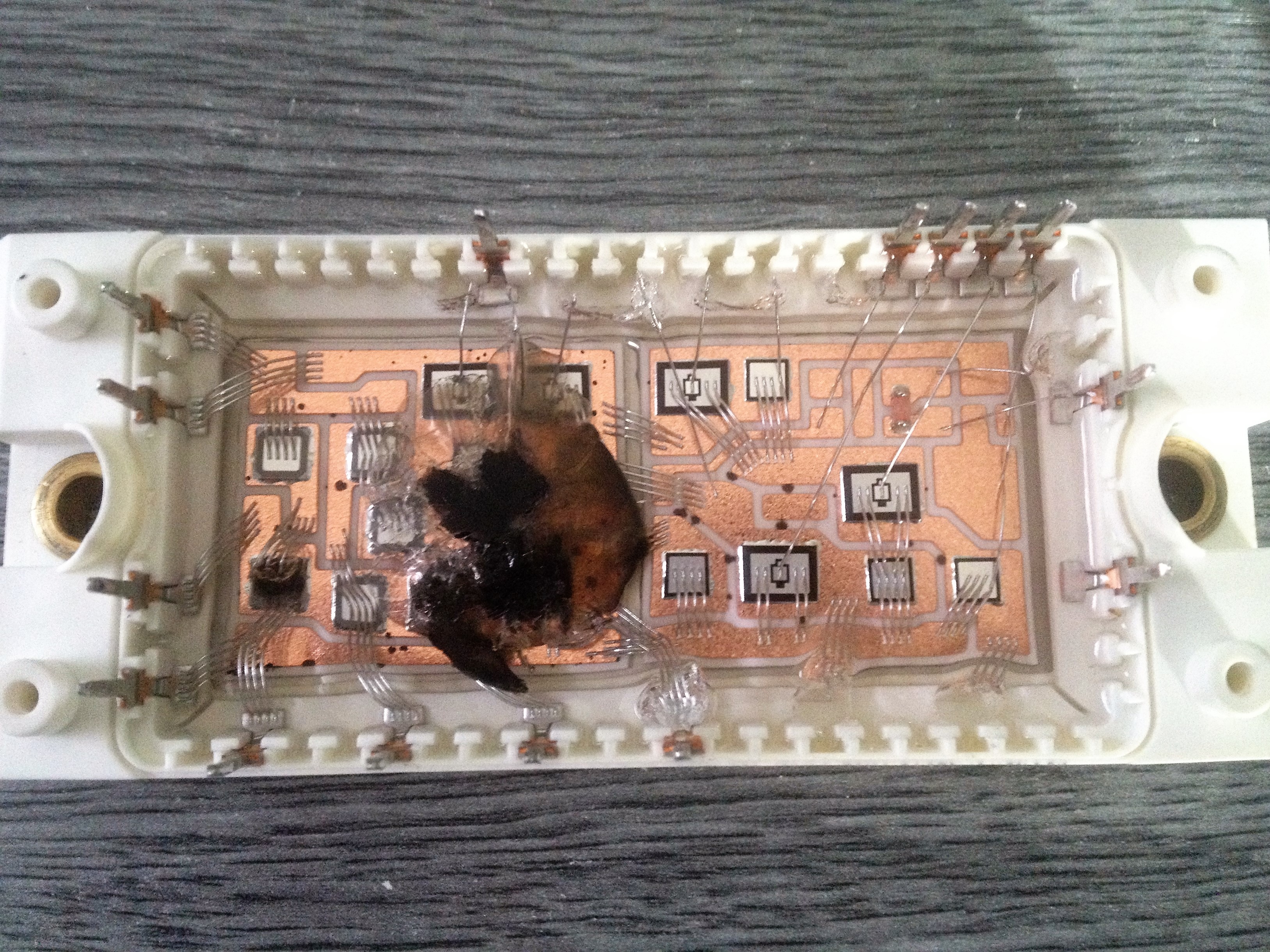

- Failures of an electrical or mechanical nature. These are usually caused by manufacturing faults such as defective soldering or incorrect operation of the equipment, which can lead to burnout of tracks on the printed circuit board. Such faults can be found by visual inspection and by measuring the resistance and continuity of the PCB conductors and the cables to be connected.

When it comes to electronic component failures, the most common failures are in the power elements, which operate with high currents and require good cooling. Therefore, during any repair or maintenance of frequency inverters, it is mandatory to check the operation of the cooling system and whether there is good thermal contact between the power keys and the cooling heat sinks.

Repair of digital control system of inverter operation in most modern devices involves the necessity to analyse the device operation log, in which its memory is recorded. From the nature of the error codes it is possible to determine either the nature of the fault or the cause of the failure.

Considering the rather high complexity of such equipment and the requirements for qualification of repairers, most companies, enterprises and organizations, which operate such devices, order repair of inverters at specialized services, which have all the necessary equipment and are able to provide quality repair with the provision of subsequent warranty on the replaced units.

As for warranty cases, they should be addressed either to the company that supplied the equipment, or directly to the manufacturer. The latter option may be more complicated when dealing with an overseas company. All the frequency inverters you can buy from our company are covered by a warranty. If necessary, we can arrange service and repair of such equipment after the warranty period expires. We solve all warranty cases promptly, thus saving you the trouble of transporting the equipment to the manufacturer, most of whom are located outside our country.