|

With high technology for control of three-phase induction motors and permanent magnets synchronous motors - Magnet, the CFW11 Series achieves the performance increase for the most complex drive systems. Design exclusive for industrial or professional use, the CFW11 presents many innovations adding significant benefits to customers, a lot for its simplicity of installation and operation, based in the Plug-and-Play philosophy also allowing simple and quick installation of its accessories.

Additional links:  Technical documentation and Downloads Technical documentation and Downloads

Request additional information and get a price quote Request additional information and get a price quote

|

Model range

CFW11 Machinery series (1 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| CFW11 0006 S2 | 1,1 | 6 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0007 S2 | 1,5 | 7 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0010 S2 | 2,2 | 10 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0006 B2 | 1,1 | 6 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0007 B2 | 1,5 | 7 | 0-999 | 145x270x227 | reduced! | |

CFW11 Machinery series (3 phase 200-240 V)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| CFW11 0007 T2 | 1,5 | 7 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0010 T2 | 2,2 | 10 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0013 T2 | 3 | 13 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0016 T2 | 4 | 16 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0024 T2 | 5,5 | 24 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0028 T2 | 7,5 | 28 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0033 T2 | 9,2 | 33.5 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0045 T2 | 11 | 45 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0054 T2 | 15 | 54 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0070 T2 | 18,5 | 70 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0086 T2 | 22 | 86 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0105 T2 | 30 | 105 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0142 T2 | 37 | 142 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0180 T2 | 55 | 180 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0211 T2 | 55 | 211 | 0-999 | 335x675x358 | reduced! | |

CFW11 Machinery series (3 phase 380-480 V)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| CFW11 0003 T4 | 1,5 | 3.6 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0005 T4 | 2,2 | 5 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0007 T4 | 3 | 7 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0010 T4 | 4 | 10 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0013 T4 | 5,5 | 13.5 | 0-999 | 145x270x227 | reduced! | |

| CFW11 0017 T4 | 7,5 | 17 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0024 T4 | 11 | 24 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0031 T4 | 15 | 31 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0038 T4 | 18,5 | 38 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0045 T4 | 22 | 45 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0058 T4 | 30 | 58.5 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0070 T4 | 37 | 70.5 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0088 T4 | 45 | 88 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0105 T4 | 55 | 105 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0142 T4 | 75 | 142 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0180 T4 | 90 | 180 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0211 T4 | 110 | 211 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0242 T4 | 132 | 242 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0312 T4 | 160 | 312 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0370 T4 | 200 | 370 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0477 T4 | 250 | 477 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0515 T4 | 280 | 515 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0601 T4 | 315 | 601 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0720 T4 | 370 | 720 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0795 T4 | 450 | 795 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 0877 T4 | 500 | 877 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 1062 T4 | 560 | 1062 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 1141 T4 | 630 | 1141 | 0-999 | 626x1414x421 | reduced! | |

CFW11 Machinery series (3 phase 500-600 V)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| CFW11 0002 T5 | 1,5 | 2.9 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0004 T5 | 2,2 | 4.2 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0007 T5 | 4 | 7.0 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0010 T5 | 5,5 | 10 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0012 T5 | 7,5 | 12 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0017 T5 | 11 | 17 | 0-999 | 190x316x227 | reduced! | |

| CFW11 0022 T5 | 15 | 22 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0027 T5 | 18,5 | 27 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0032 T5 | 22 | 32 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0044 T5 | 30 | 44 | 0-999 | 220x405x293 | reduced! | |

| CFW11 0053 T6 | 37 | 53 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0063 T6 | 45 | 63 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0080 T6 | 55 | 80 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0107 T6 | 75 | 107 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0125 T6 | 90 | 125 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0150 T6 | 110 | 150 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0170 T6 | 110 | 170 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0216 T6 | 160 | 216 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0289 T6 | 200 | 289 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0315 T6 | 220 | 315 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0365 T6 | 250 | 365 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0435 T6 | 315 | 435 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0584 T6 | 450 | 584 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 0625 T6 | 450 | 625 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 0758 T6 | 560 | 758 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 0804 T6 | 560 | 804 | 0-999 | 626x1414x421 | reduced! | |

CFW11 Machinery series (3 phase 660-690 V)

| Model | Capacity, kW |

Current, A |

Deceleration time, sec | Dimensions (W x H x D), mm |

Price | |

|---|---|---|---|---|---|---|

| CFW11 0002 T6 | 2,2 | 2.9 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0004 T6 | 3 | 4.2 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0007 T6 | 5,5 | 7.0 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0010 T6 | 5,5 | 8.5 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0012 T6 | 9,2 | 11 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0017 T6 | 11 | 15 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0022 T6 | 15 | 20 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0027 T6 | 18,5 | 24 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0032 T6 | 22 | 30 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0044 T6 | 30 | 35 | 0-999 | 300x550x305 | reduced! | |

| CFW11 0053 T6 | 37 | 46 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0063 T6 | 45 | 54 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0080 T6 | 55 | 73 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0107 T6 | 90 | 100 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0125 T6 | 90 | 108 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0150 T6 | 110 | 130 | 0-999 | 335x675x358 | reduced! | |

| CFW11 0170 T6 | 132 | 147 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0216 T6 | 185 | 195 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0289 T6 | 200 | 225 | 0-999 | 430x1234x360 | reduced! | |

| CFW11 0315 T6 | 220 | 259 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0365 T6 | 280 | 312 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0435 T6 | 315 | 365 | 0-999 | 535x1264x426 | reduced! | |

| CFW11 0584 T6 | 450 | 478 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 0625 T6 | 500 | 518 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 0758 T6 | 560 | 628 | 0-999 | 626x1414x421 | reduced! | |

| CFW11 0804 T6 | 630 | 703 | 0-999 | 626x1414x421 | reduced! | |

WEG CFW11 series system drive.

The CFW11 is a system drive designed for the control of squirrel cage induction motors as well as permanent magnet motors. Since it was developed for running on Normal and Heavy Duty mode, a wide variety of applications can be achieved. Designed for exclusively industrial or professional use, it provides increased productivity with excellent performance and quality improvement of the process in which it is used.

Innovative and User Friendly.

The CFW11 presents many innovations that are helpful and beneficial to customers, mainly due to the simplicity of its installation and operation. The CFW11 was developed based on Plug & Play philosophy (connect and use) allowing simple and fast installation of the VSD and its accessories. The Keypad has a navigation and programming system with soft-key buttons. It is possible to access the parameters sequentially or through groups of parameters. The Keypad also makes the Oriented Start-up function available, guiding the user through the necessary programming.

Flexibility.

The CFW11 is adaptable to the customer’s needs through a broad range of accessories which are easily installed. Besides that, the standard product comes with SoftPLC, allowing the customer to create his/her own user applications through the WLP software (Ladder programming).

Own technology with WEG frequency inverter CFW11 series.

Vectrue Technology.

- Linear and adjustable V/F, VVW (Voltage Vector WEG) and vector control are available on CFW11

- Two types of vector control: sensorless and closed loop vector control (encoder Interface required)

- Sensorless vector control permits high torque and quick response in open loop, even at low speeds

- The self-tuning function sets the vector control or VVW with the motor and to application load used

- By the adjustable V/F control, it is possible, for example, to adjust a quadratic V/F curve, providing energy savings for quadratic torque loads (e.g.: centrifugal pumps and fans).

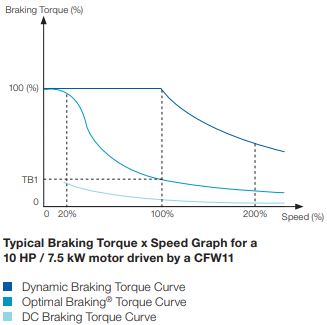

Optimal Braking.

Applications involving high inertia loads, when applied short time deceleration, a large amount of energy returns from the motor to the VSD. To handle this energy, reguilar VSDs have to dissipate it as heat in power resistors. Such resistors are usually large and some installation criteria must be considered due to their heat dissipation. As an alternative to the use of braking resistors, CFW11 features a special braking method in vector control mode known as Optimal Braking®. This innovation delivers a high performance braking torque without requiring a braking resistor. The following graph shows the advantages of using Optimal Braking® compared to other braking methods, thus ensuring an optimized and low cost solution for braking applications.

WMagnet Drive System.

Variable Speed Drive controlling permanent magnet motors. The WMagnet System (WMagnet motor + CFW11) has the highest efficiency levels in the market. It is a perfect match for applications where speed variation, low noise level and reduced size are required. In Sensorless mode the WMagnet System is able to perform torque control at zero speed without the need of forced ventilation.

Main Characteristics of the Set CFW11 + WMagnet Motor:

- Voltage range: 380 to 480 V ac

- Power rating: 11 to 160 kW (15 to 220 HP)

- Methods of control: sensorless vector and closed loop control (vector with encoder)

- WMagnet control algorithm included on the CFW11 standard version

- Communications protocols: Modbus-RTU, Modbus-TCP, Profibus-DP-V1, DeviceNet, CANopen Ethernet / IP, Profinet-IO and BACnet.

Technical Features of WEG vfd CFW11 series.

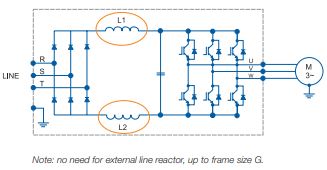

Built-In DC Link Reactor.

- Allows the VSD to be installed in any network (there is no minimum impedance restriction)

- Typical power factor (PF) for rated condition: 0.94 for models with three-phase supply, 0.70 for models with single-phase 0.70 for models with single-phase supply/three-phase supply = 0.94

- Displacement power factor > 0.98 J Meets the 61000-3-12 standard, related to low order current harmonics in the network

- Available until frame size G, for the frame size H is mandatory use external line reactor.

Conformal Coating.

A special varnish is applied on the electronic boards of the CFW11, extending its lifespan, protecting against dust, humidity, high temperatures and chemical substances. Classified as 3C2 according to IEC 60721-3-3. Standard for the complete line.

Single DC Busbar.

Usually used in multi-motor systems, common DC bus configuration is a good solution for energy savings. In this configuration, individual VSD rectifer bridges are replaced with a common input rectifer unit. Each VSD is then directly fed from the DC bus to its DC link terminals. This solution allows the energy in the DC bus to be shared among the VSDs connected to it, thus optimizing the power consumption in the system. The standard CFW11 sizes A to E and special hardware version (DC) for frame sizes F, G and H can be connected to a DC bus system. (When required, the factory can be consulted for further details).

Intelligent Thermal Management.

- Monitoring of the heatsink and internal air temperatures of the electronic boards, providing total protection of the IGBTs and the CFW11 as a whole

- The heatsink fan is turned on and off automatically, depending on the temperature of the power modules

- The speed and the fan’s operation hours number are monitored and indicated in corresponding parameters. Alarm or fault messages are generated related to these variables

- The fan can be easily removed for cleaning or replacement.